Gherardo Canale, Project Engineer at Incide Engineering, tells the birth of steel with a dip in history.

To progress means to move forward. Humanity has always aspired to this: to go beyond previous limits towards new knowledge. In each branch of the Tree of Knowledge, progress can manifest itself in different ways, sometimes with bursts of creativity and innovation, sometimes with slow improvements that, layer by layer, create a solid foundation for subsequent generations.

Sometimes, however, in history contingencies are generated that determine a real point of discontinuity between the “before” and the “after“. The branch of knowledge divides itself, leaving room for a nascent branch, a progenitor of a new branch of knowledge from which everything appears different.

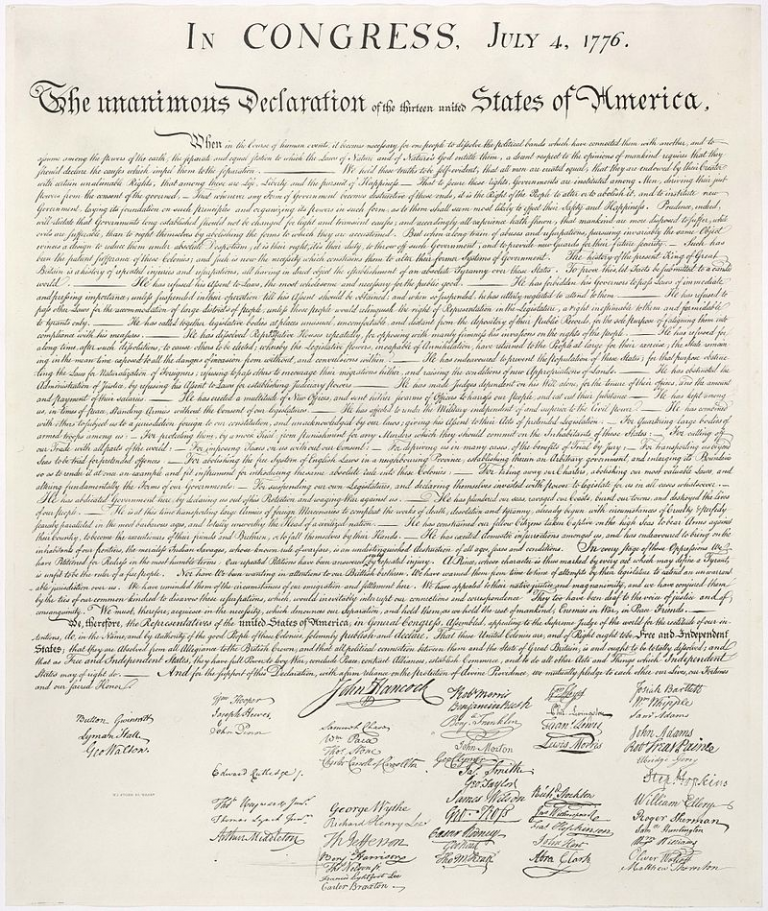

Thus, it may happen that a very important event for a branch of knowledge falls into oblivion when compared to another exceptional event, albeit located five thousand kilometers away. Everyone’s attention is in fact concentrated in the New World where, at the end of a long and bloody war, a world superpower is about to be born. In fact, a declaration of independence is about to be signed which will later become “The Declaration of Independence” par excellence, sanctioning a clear separation between the “old” and the “new” world.

Britain loses its colonies, despite the obstinacy of King George III, and risks a new war with France and postpones hostilities in North America beyond measure, aggravating national problems and debts.

Yet, in this very difficult context, in the heart of England, something completely new was about to be born, capable of forever changing the history of structural engineering and of England itself.

Coalbrookdale is a small English village set against a deep Shropshire gorge. Coal-brook-dale, the name of the village itself is more than enough to underline the characteristics of this place: Coal-Valley-Stream. Here the entire population has always been involved in mining and metallurgical activities. Here is born the first raw form of what will one day be considered a key element of all the great structures of the world. The Darby family has developed an industrialized and modern system for the production of cast iron, using carbon coke.

This element is the fulcrum of the first English Industrial Revolution. It is the lever of the English revival. Of its development. Cast iron is produced here and exported throughout the country.

There is a problem, though. A problem that humanity has always had to face in every corner of the world. To get around you need roads. To fuel the economy, we need to connect people. Create infrastructure to speed up the exchange of goods. Overcome obstacles. Sometimes these obstacles are a forest, sometimes a mountain, sometimes a river.

In this case, it’s the longest river in the Kingdom. The Severn originated in Wales, and just near Coalbrookdale, in geological times, it dug a deep gorge. The trade and export of cast iron has slowed down. Crossing the river across the river would be best, but it’s complex and risky.

However, the time is ripe to allow a gamble. Need a bridge. A bridge out of the ordinary, though. Not brick. Not made of wood. A new bridge. The first in history. The biggest. A point of discontinuity from the past. The birth of a new branch of engineering. An iron bridge.

Abraham Darby III, the last heir of the Darby family and president of the Coalbrookdale Company, decides to invest part of his assets in this venture that will remain historic. The investment will not pay off in economic terms, but it will make it immortal together with the chosen architect.

Thomas Farnolls Pritchard, architect and engineer specializing in wooden bridges: he was the first to propose in 1776 what would later be renamed the Ironbridge: the first Iron bridge in the world.

However, cast iron has a big problem compared to steel: it doesn’t resist traction well. For these reasons, the design must respect wise rules derived from experience in the design of wooden bridges. His original design is slightly modified following his untimely death (he has never seen the bridge built), but the general structure remains unchanged: a single-span iron bridge.

The Ironbridge weighs 300 tons and connects two banks of the narrow gorge, more than 30m apart. The construction technique didn’t make the most of the characteristics of the innovative material (it could be optimized), but it was solid, what was needed for the development of trade and the transport of this heavy material that was produced in the village.

This project represents the birth of a new discipline: structural engineering applied to steel. A milestone that deserves to be celebrated and known by all structural engineers and professionals.

The iron, first in the form of cast iron, will turn into steel thanks to the limitation to 2% of carbon and the ability to bind other materials thanks to the achievement of higher melting temperatures.

However, casting is not enough: one must also found, establishing a new construction science.

Only in 1850 the first precursors of this matter formulate their theories. First of all, in 1850, De Saint-Venant, with his Theory of Beams subject to bending. Then the Theory of Instability.

For the first steel bridge you will have to cross the ocean, going right where that declaration of independence was signed on July 4, 1776. Again in a tough period. At the end of another long and bloody internal war: the American Civil War.

States, to be truly “united”, will need a symbol of rebirth. A new point of discontinuity from the past. Emulate their old enemies 100 years later. To recall the memory of the Darby family and the genius of Thomas Farnolls Pritchard to build an immortal work.

The time is ripe for the birth of the world’s first true steel bridge: the Brooklyn Bridge.

This work is exceptional from all points of view. The longest bridge in the world for the time.

The steel tie rods used for the first time. The discovery of a previously unknown disease. A strong and determined female engineer behind this masterpiece.

Much to tell.

But not this time. Maybe the next one.