As anyone approaching the decision to carry out a building or energy improvement for the first time knows, there are many procedures and data to be analysed and exchanged. However, these processes are no longer subject to confusion and delays in delivery, but on the contrary can be better controlled thanks to interoperable management. In fact, in order to get the most out of the design process without errors or delays, all you need to do is to call on experts who have a firm grasp of the new methodologies.

Let’s take a closer look at what interoperable management consists of and what advantages it brings to energy efficiency projects.

The benefits of interoperable management

Interoperability is the exchange of design information between various software platforms, applications and between the different professionals involved in both the design process and the construction phase.

This transversality is inherent in the approach to a BIM workflow that guarantees the exchange and accessibility of data. This is achieved through the use of IFC (Industry Foundation Classes) between all participating operators.

The application of this type of management to the projects that will benefit pf energy efficiency is fundamental for an orderly control of the information that this type of design requires: those who manage redevelopment projects are well aware of the large amount of data that comes from the different disciplines: architectural, plant engineering, safety, computational and site management.

The amount and diversity of information involved benefits therefore requires an integrated process involving BIM models, in order to obtain and guarantee these benefits to the client:

- Facilitation of the exchange and consultation of data useful for energy analyses, metric calculations and architectural design;

- Construction site safety

- Avoidance of errors that could cause delays during construction;

- Speeding up timetables and streamlining public procedures;

- Real-time control of changes to planned interventions.

These advantages are central as they facilitate the work of all those involved in the project and guarantee the best results for the client. To achieve these benefits, it is essential to turn to professionals experienced in BIM and interoperability, such as Incide Engineering.

The importance of relying on experienced designers

Incide Engineering has consolidated experience in dealing with projects that involve the various specialisations involved in the definition of the case at the same time.

In particular, Incide has established know-how in interoperable project management and BIM methodology.

In this specific case, the integration for a global BIM management of the project involves the realisation of architectural project drawings, energy analyses and estimated metric calculations.

To this end, it was necessary to provide a workflow involving the exchange of information between different software, since the professionals involved in this process are different, even if within the same organisation.

The internal exchange of data contained in the main BIM model with other software useful for other analyses was carried out through the use of the open format IFC (Industry Foundation Classes).

Communication via the IFC standard allows the use of specialised programmes for the management of the energy, economic and quantitative aspects linked to the realisation of the work, in order to have real-time control of any changes in the planned interventions or in the hypothesised timescales.

How does workflow work in BIM?

By approaching the project in an interoperable way, by setting up a BIM work process, a complete, controlled and ordered workflow can be achieved.

It is well known that BIM modelling brings concrete advantages in terms of time and error reduction in the exchange of data and control of the design process.

The interoperable management of this particular design process aimed at improving energy efficiency was based, first and foremost, on the identification of purposes:

- Energy analysis;

- Building renovation and architectural renovation for energy purposes, building practices and project drawings;

- Estimated metric calculation;

- Safe site management and efficient scheduling.

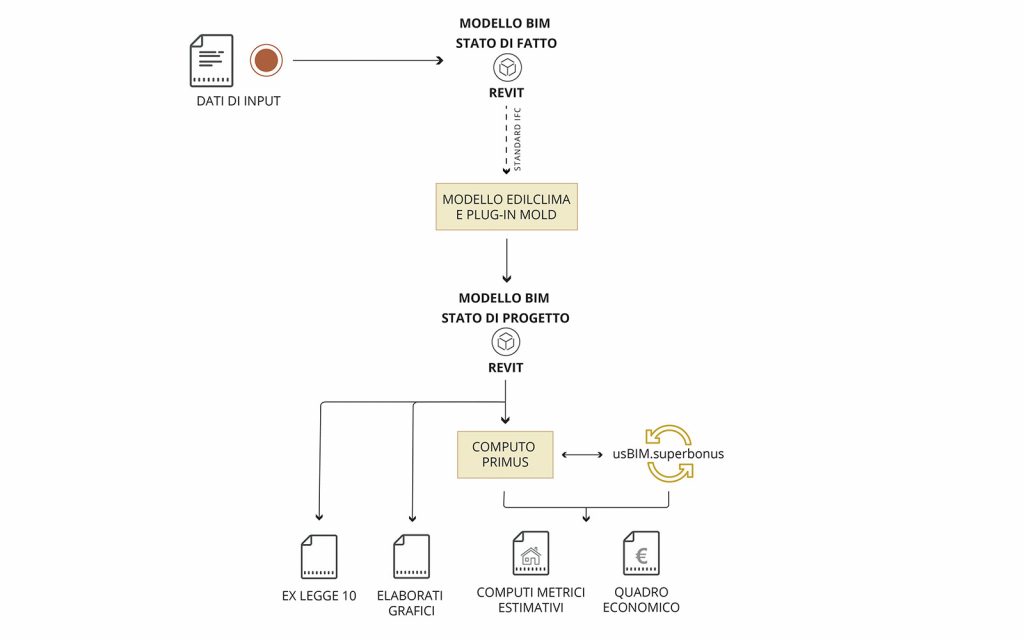

Based on these, it was decided to manage the process using three main technical software packages:

- Autodesk®

- Revit

- Edilclima® EC 700 and plug-in DarTWin Mold Simulator

- ACCA® PriMus

- usBIM.superbonus

They were respectively useful for BIM architectural modelling, energy calculations and thermal bridge solving and, finally, metric estimation calculations.

The exchange of parameters and data between the various softwares took place through the use of the IFC standard, which allowed a control of the technical information exchanged and a speeding up in terms of calculation times and data control.

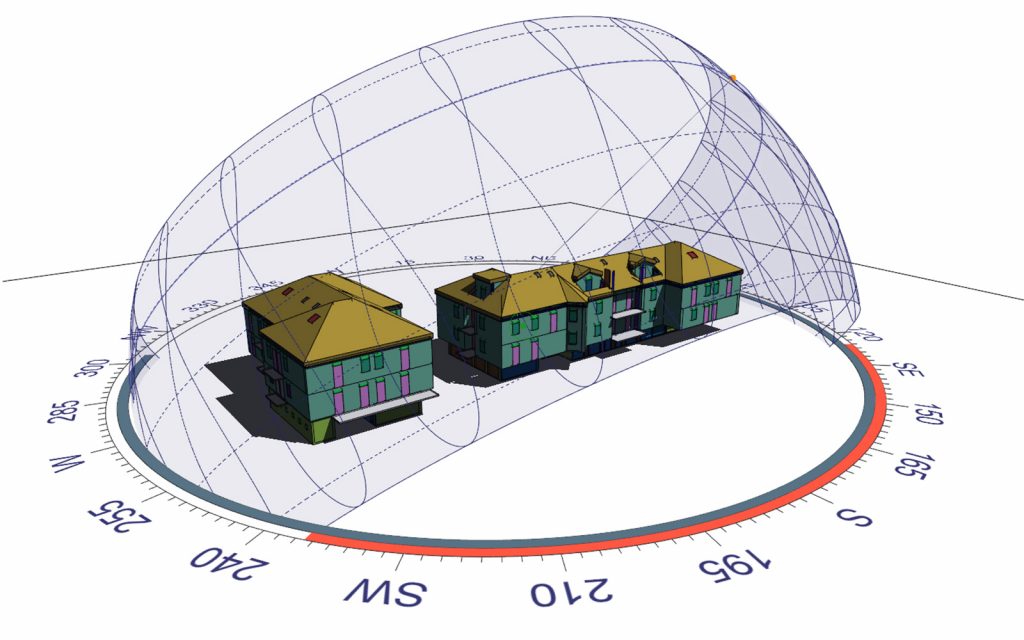

The BIM workflow is developed starting from the architectural modelling of the actual state of affairs based on the inputs available to the building and any surveys.

This modelling is aimed at obtaining IFC files that can be used for analysis.

The Revit model is set up in anticipation of obtaining the facilitation and the approval of the competent Municipality, so it is developed in phases (actual state and project state), in order to reduce the time required to prepare the necessary graphic works.

Within the Revit model, parameters useful for the analysis are inserted, such as the owners of the units, stratigraphy of the materials and the relative phase of realisation, dimensions and characteristics of phorometries, closures and shutters. The rooms and zones are also modelled with the relative parameters to which the energy characteristics such as air conditioning and heating are associated.

Exporting the IFC file from the existing model allows the appropriate energy analyses to be carried out in Edilclima, aimed at obtaining a jump of two energy classes and planning the necessary architectural interventions and their technological characteristics. By means of this software it is possible to study thermal bridges and, therefore, the materials which it is necessary to insert for their resolution.

In order to have more precise thermal and energy analyses, the Mold Simulator plug-in is used to perform the mould checks. The output of the energy analysis process is the package of documents relating to Ex Law 10 and verification of the correctness of the interventions to be carried out.

From energy analysis to final calculation

The energy analysis is followed by the updating of the BIM model with the modelling of the project status, from which the computation with PriMus will follow through the control in usBIM.superbonus, a platform from which it is possible to manage owner master data, subsidies, expenditure ceilings and WBS divided into driving and driven interventions, which are fundamental for a correct computation.

Performing energy analyses and estimations integrated in a BIM process offers numerous opportunities:

- To have more control over material quantities and thus over the cost of the works

- Knowing the energy savings that the use of materials will produce on the building

- Speed of updating based on hypothetical design changes during the process.

The outputs of this integrated process will therefore be documents relating to energy analyses, graphic drawings useful for obtaining the deductions, metric and estimated metric calculations and finally the economic framework.

Energy Efficiency Projects: Trust the experts

In order to get the most reliable energy efficiency result, it is important to call on experts who have a firm grasp of the new methodologies.

Incide Engineering has a proven track record in dealing with projects involving various specialisations and workflow in BIM for Superbonus projects.

Contact Incide Engineering for more information and to tell us about your project.