Accurate surveying is the basis of good design, and 3D scanning technologies are revolutionising this area, in particular thanks to the laser scanner, a tool capable of rapidly acquiring complex geometries and returning a high-definition digital model.

But how exactly does a laser scanner survey work? What are the concrete advantages compared to traditional techniques and how is this process integrated into architectural and plant design?

Through three project cases by Incide Engineering – in contexts ranging from the restoration of a historical building in Puglia to the large-scale design for Leonardo Global Solutions and Zaha Hadid‘s Theatre di Rabat – we explore the potential and applications of laser scanner surveying.

How the laser scanner works

A laser scanner is an instrument that enables the three-dimensional survey of the surrounding environment by emitting laser pulses. These are reflected from objects in space and, by measuring the time they take to return to the sensor, the instrument accurately calculates the distance of each point in space. The result is a point cloud: a detailed digital representation of the detected surfaces, consisting of millions of spatial coordinates. This cloud can then be processed and transformed into three-dimensional models that can be used in leading BIM, CAD and GIS design software.

One of the most interesting aspects of this technology is its versatility: it’s now possible to carry out accurate surveys even with mobile devices equipped with a LiDAR sensor, making accessible a technology that until a few years ago was the prerogative only of advanced topographic instruments.

Laser scanning is particularly effective in the presence of complex geometries, irregular decorative elements or spaces that are difficult to access, and is a fundamental tool in restoration, redevelopment and integrated design projects.

Laser scanner for surveys and point clouds

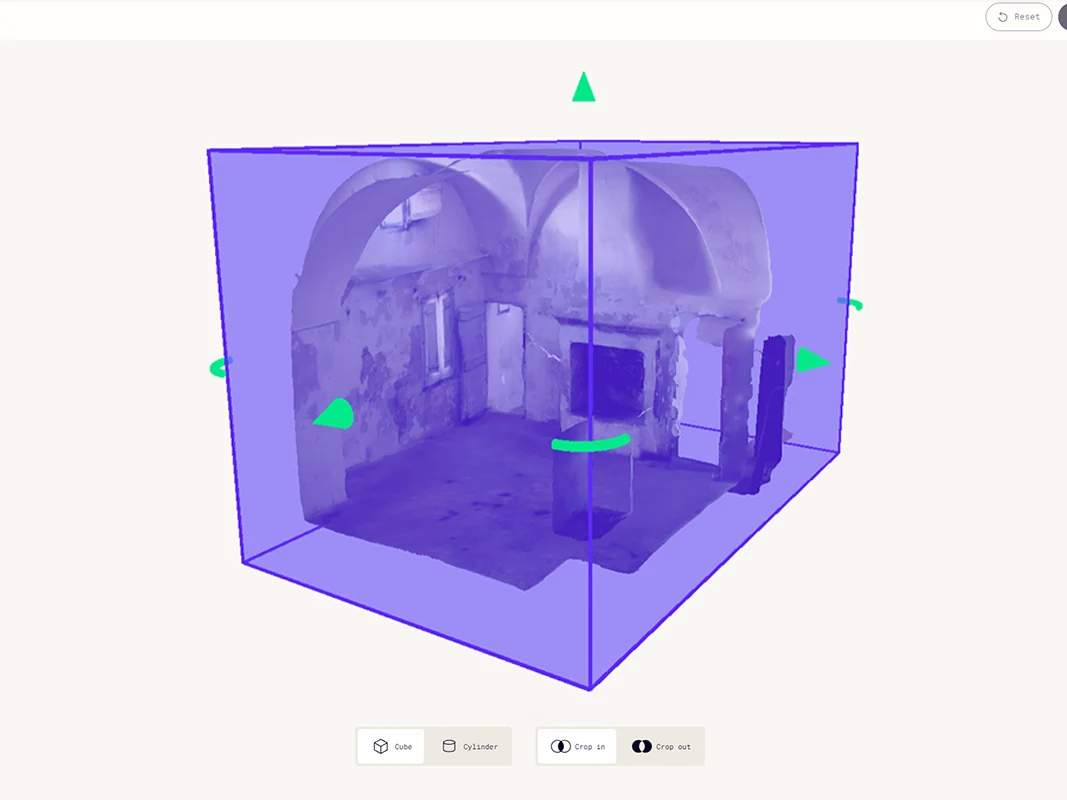

In the context of the renovation of a historical building in Apulia, Incide Engineering adopted laser scanner surveying as the technology for digitising the design process, conducted by Construction Engineer Pierandrea Donegà in his thesis. The overall objective of the project was to create a BIM model faithful to the geometric complexity of the building, characterised by irregular architectural elements such as hybrid vaults, historic fireplaces and non-orthogonal surfaces.

The survey was conducted in-house with the help of a smartphone equipped with a LiDAR sensor, a choice dictated by the need to contain time and costs without sacrificing the required quality. The scan produced a point cloud that was subsequently processed in a software environment for BIM modelling, allowing an accurate three-dimensional restitution of the state of affairs.

The use of this technology brought numerous advantages: speed of execution, accessibility even in interior spaces difficult to reach with traditional instrumentation, and direct integration into design software. The project also represented an opportunity to refine the point cloud management and post-processing process, improving the selection of useful data and the optimisation of the model.

In fact, laser scanner surveying is effective in places with complex geometries and highlights the value of a well-structured digital workflow that can guarantee data accuracy, operational speed and a truly innovative approach to design.

3D laser scanner survey: the Luni base for Leonardo Global Solutions

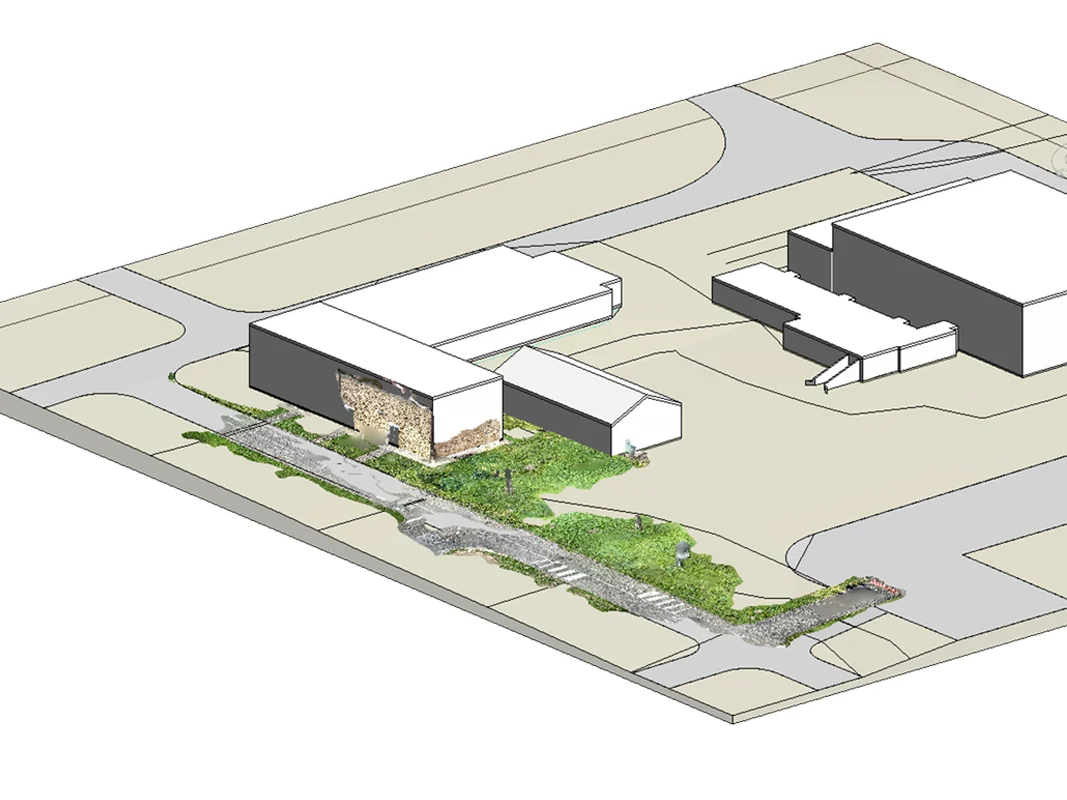

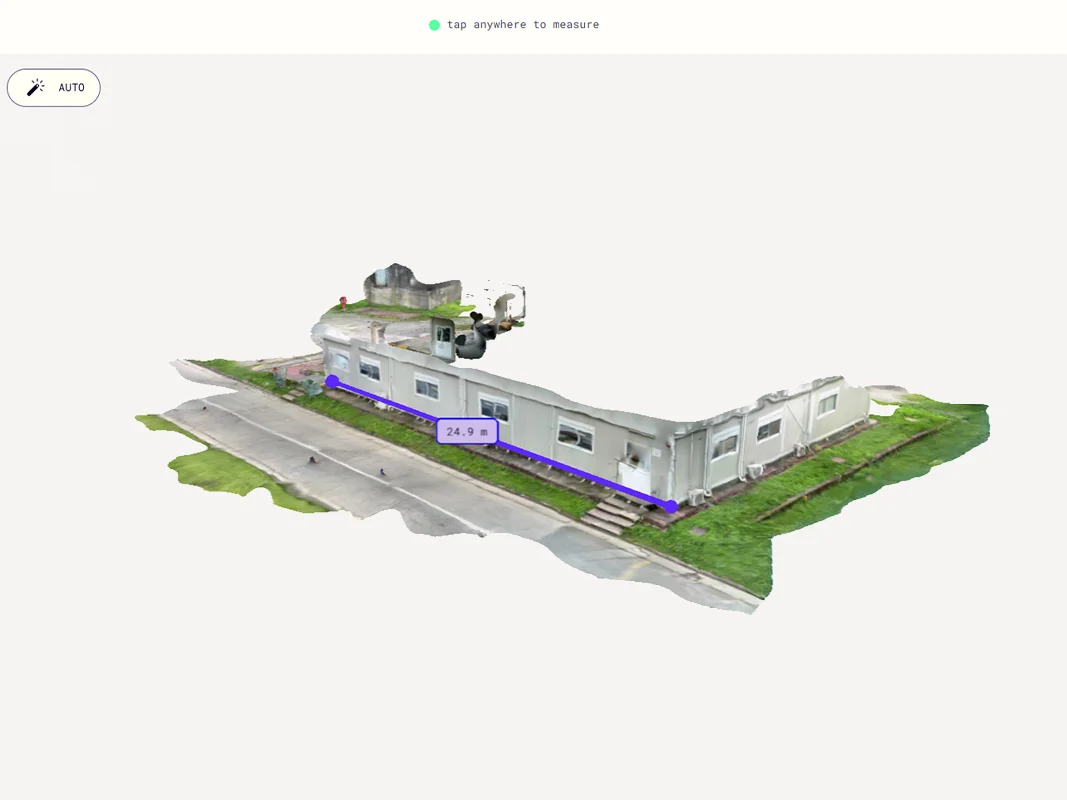

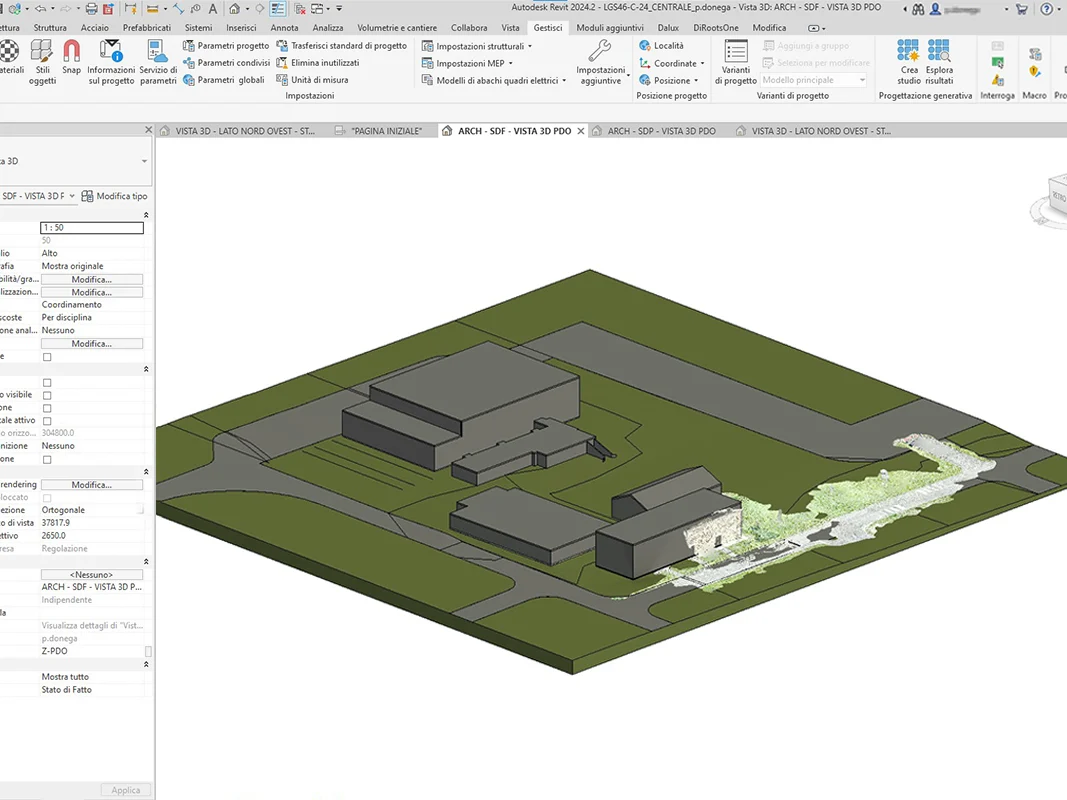

Incide Engineering took care of the architectural, structural and plant engineering design of a new warehouse and office building inside the Maristaeli Luni military base, in Sarzana (SP), on behalf of Leonardo Global Solutions. The project, developed in 2024, also included a careful analysis of the state of affairs in order to obtain more precise data on the plano-altimetric trend of the roads and the morphology of the terrain in the area of intervention.

For this activity, a Polycam software application, based on the LiDAR technology integrated in the iPhone Pro devices, was used to acquire a point cloud of the surveyed area. The generated file, in .ply format, was subsequently imported into the Autodesk Revit environment for the extraction of accurate measurements, and was also integrated into the model developed in Autodesk Revit for an even more detailed topographical representation.

The use of this technology made it possible to significantly reduce time and costs compared to a traditional survey, while guaranteeing a high level of accuracy and reliability in the data collected.

Laser scanner façade survey: Zaha Hadid’s Grand Theatre Rabat

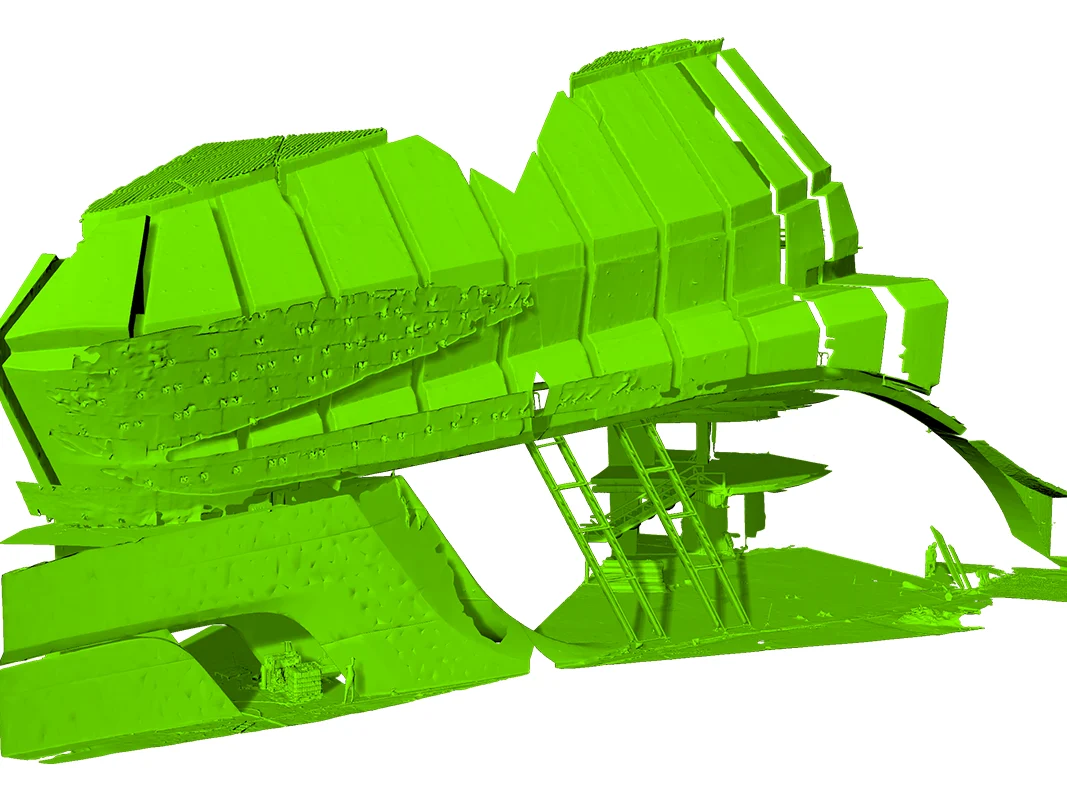

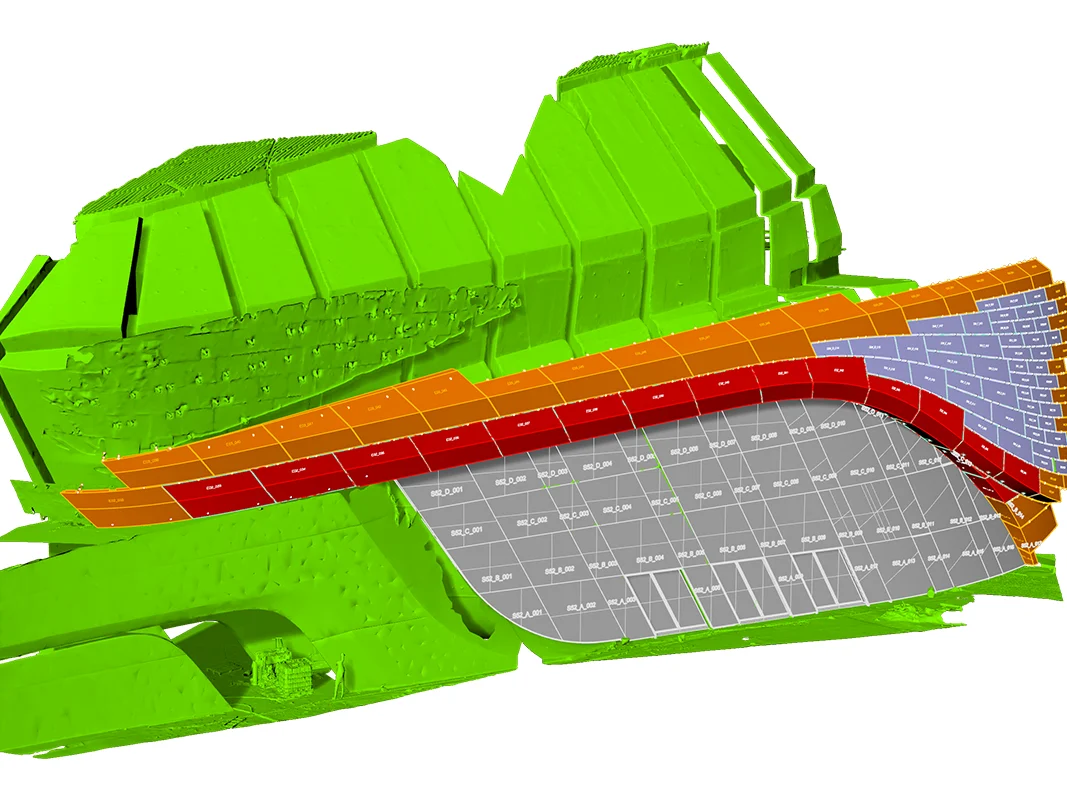

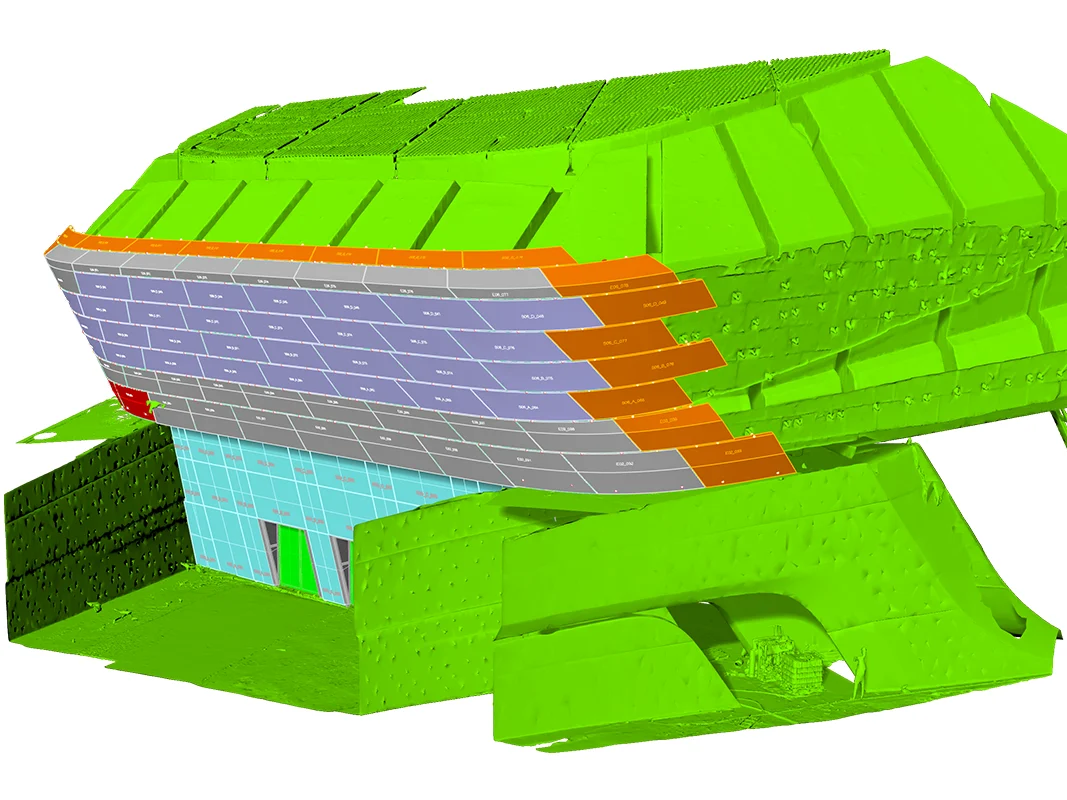

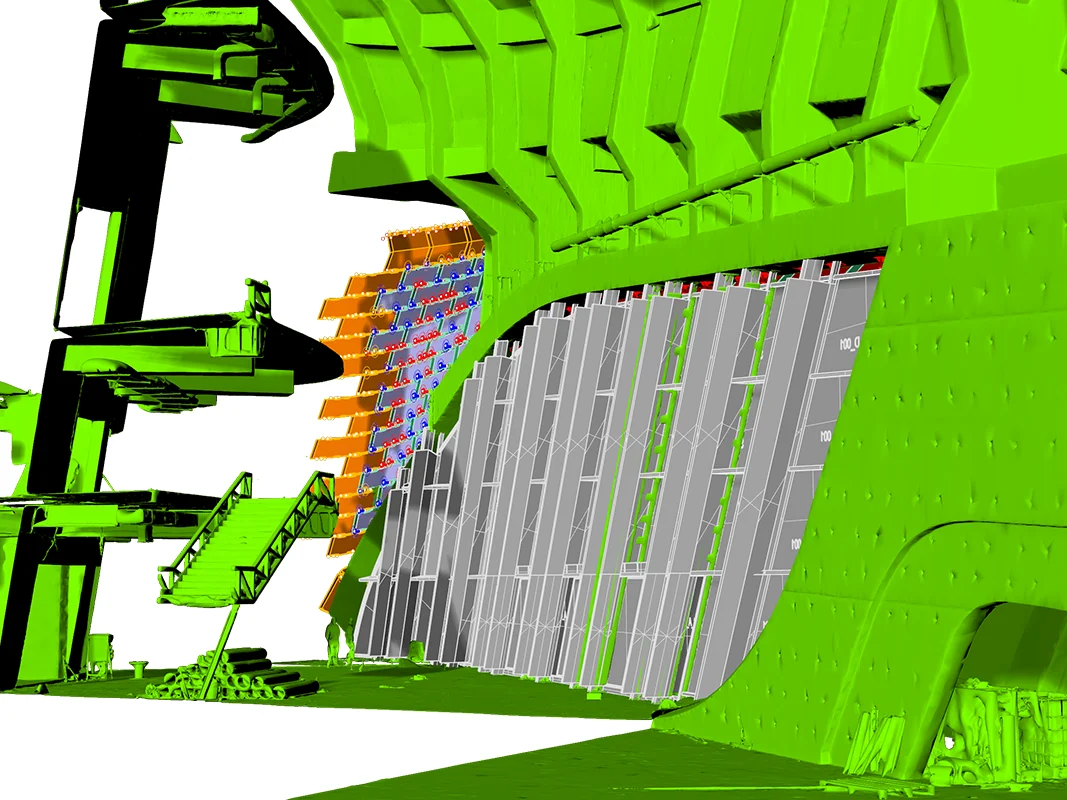

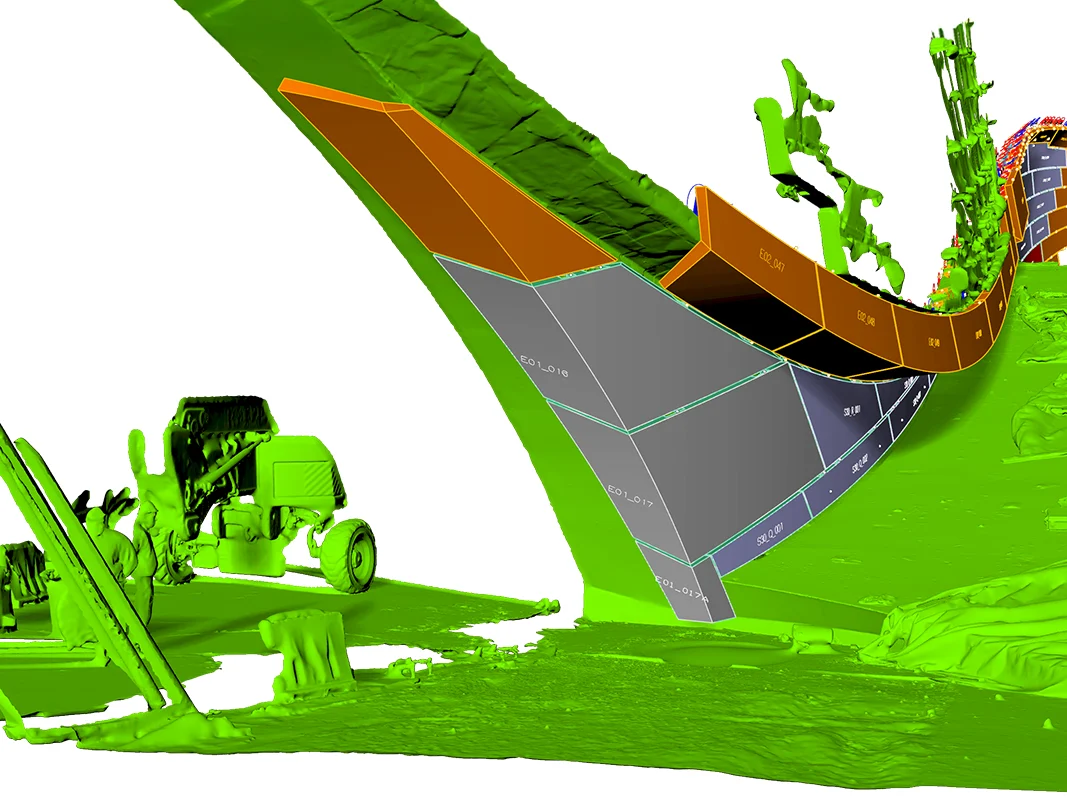

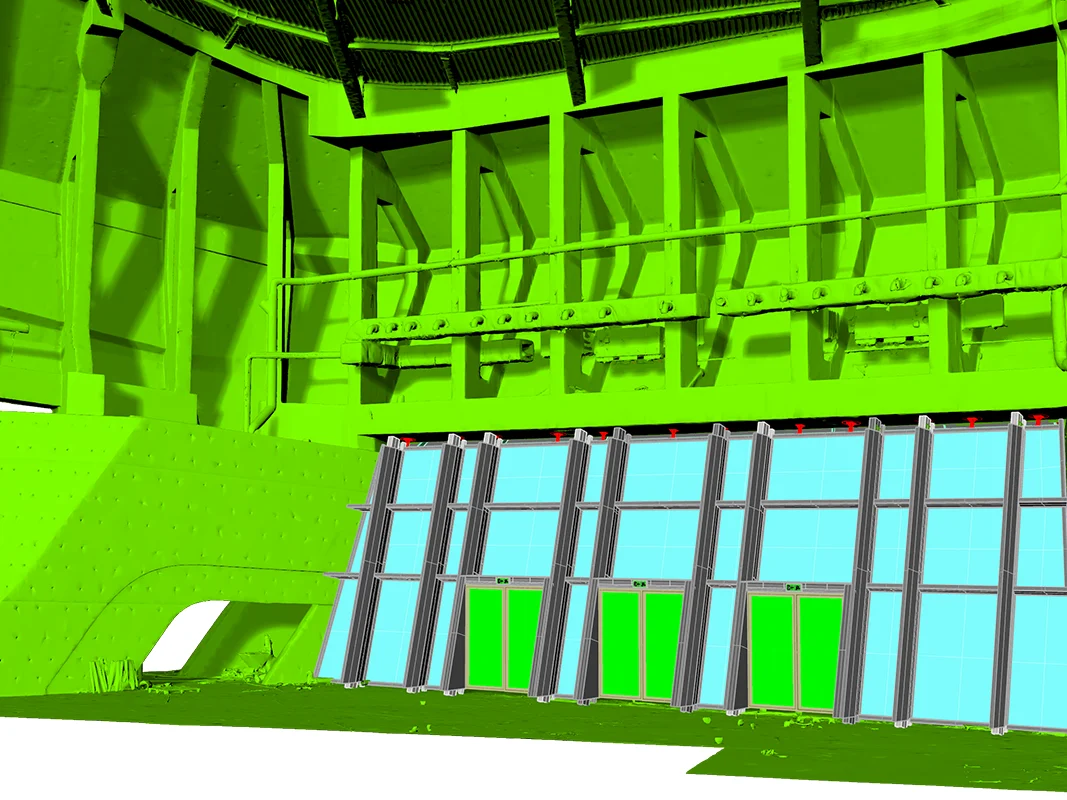

For the Grand Theatre di Rabat, Incide was responsible for both the design work of the GRC facades and the substructure supporting these panels in the tail area and the entire steel space. The production executives of the panels were produced for the entire building for validation purposes.

Since the paneling area was very large and some areas were particularly articulated, it was necessary to carry out laser scanner surveys of the cast concrete, because there are always large tolerances between the design and construction phase, especially for such complex works. In this way, Incide verified the clashes between the theoretical panels and the concrete surveyed, in order to modify certain lines of the design of the panels to be produced.

In addition, the laser scanner survey proved useful to verify the connections and dimensioning of the steel substructures that were to support the panels. All interventions were coordinated using Rhinoceros and Grasshopper software, with the aid of parametric modelling.

Laser scanner surveying proves to be a strategic tool for tackling complex projects with greater efficiency, precision and technical awareness. From the integrated design of new structures to the enhancement of existing heritage, as in the case of the renovation of Palazzo Roccabonella and the cases analysed above, this technology represents a concrete opportunity to innovate the design process from a digital perspective.