Corten steel is now one of the most strategic materials for contemporary architecture and engineering. In addition to its recognisable aesthetic impact, it stands out as a high-performance solution with low maintenance costs and a durability profile that is particularly suited to the built environment. However, the effective use of Corten requires precise technical knowledge for truly high-performance design, both in structural terms and in terms of life cycle management.

Therefore, understanding its actual technical characteristics, economic and operational advantages, limitations of use and strategic applications is now essential in deciding whether to use it in high-visibility projects, from façades and roofing to civil engineering works and street furniture.

Technical characteristics of Corten steel

The name ‘Corten’ derives from two English terms: CORrosion resistance and TENsile strength: it is a group of low-alloy steels specially formulated to form, when exposed to the atmosphere, a compact and adherent surface patina that significantly slows down further corrosion and replaces the need for protective coatings. This patina, consisting of compact oxides of copper, chromium, phosphorus and nickel, drastically reduces the rate of corrosion to values as low as 60-80% compared to unprotected mild steels.

The rusted surface acts as a protective barrier and is also commonly appreciated for its aesthetic impact in architecture.

The most common industrial grades include:

- ASTM A242 – architectural and light structural applications;

- ASTM A588 – structural uses in bridges, beams, carpentry;

- ASTM A606-4 – thin sheets suitable for facades and roofing.

Compliance with these standards is crucial to ensure the correct formation of the patina: inexpensive, non-certified materials are prone to accelerated corrosion and surface instability.

Mechanical strength of Corten steel

Corten steel belongs to the S355 steel family, so it has comparable strength to the most common structural steels, with the addition of natural corrosion protection.

There are various grades of Corten, each designed for specific applications:

- Corten A: Often used in architectural applications, street furniture, façades, containers.

- Corten B: with greater mechanical strength, suitable for structures subject to stress (bridges, large beams, infrastructure).

- Corten C: an even more mechanically efficient variant, designed for structures subject to particularly high stresses.

This distinction is important in specifications: efficient design with Corten steel allows for reductions in the thickness of ventilated façades, greater durability for bridges and walkways, and aesthetic integration without additional cladding, improving the overall economic balance of the project.

From a technical point of view, it is necessary to be aware of the following aspects:

- Mechanics: Corten steel has mechanical characteristics comparable to those of high-quality structural steels – typical values indicate a yield strength in the order of several hundred MPa (e.g. 275–355 MPa depending on type and treatment) and tensile strengths consistent with structural use; ductility and shear performance are adequate for civil and architectural applications.

- Patina formation: depends on alternating dry-wet cycles and a sufficiently clean environment. If the patina is damaged, the steel automatically initiates a controlled oxidation process that restores protection.

- Patina stability: this is affected by the presence of dissolved chlorides or salts, the accumulation of dust that prevents uniform oxygenation, construction details that promote water stagnation and surfaces with unfavourable orientation (e.g. undercuts). Proper design must ensure natural ventilation of surfaces, minimal slopes, drip edges and joints that prevent water accumulation.

- Aesthetic appearance: brown/reddish colour that varies over time; finishes and patinas may differ depending on rainfall, atmospheric deposits and surface orientation.

- Self-regeneration mechanism: if the oxidised surface is scratched, the oxidation process resumes, rebuilding the protective layer.

- Weather resistance: the patina limits corrosion, but its effectiveness depends greatly on the environment (dry-wet cycles, presence of chlorides, etc.).

Pros and cons: the advantages of Corten steel and its limitations

When choosing materials, decisions are generally guided by factors such as total cost of ownership, aesthetic impact and potential litigation risks.

Here are the main strategic benefits of choosing this material:

Reduction in maintenance costs

Once the protective patina has formed, Corten steel avoids the need for the cyclical protective painting required by traditional steels, resulting in reduced maintenance costs over the life cycle of the structure. This aspect is particularly important for structures that are visible or inaccessible for frequent maintenance.

Aesthetic value and architectural branding

The visual character of Corten steel has become a recognisable style in urban branding, museums, façades and the built landscape: a “natural” finish that conveys identity and blends in with both contemporary and historical contexts.

Structural performance

For specific structural parts, there are grades of Corten steel with mechanical properties suitable for load-bearing use, allowing aesthetics and functionality to be combined without the need for additional coatings.

Operational sustainability

From an LCA and operational sustainability perspective, the absence of paint and chemical treatments improves the long-term environmental profile: fewer consumables, less construction work and lower maintenance-related emissions.

Having understood the advantages of using Corten, it is crucial to be aware of its potential limitations:

- Marine environments and salty climates: near the sea and in the presence of salt aerosols, Corten steel may suffer pitting and fail to form a stable protective patina; in such cases, natural protection is less effective and an auxiliary coating may be necessary.

- Risk of stains and run-off: during the initial oxidation phase, runoff water can cause deposits and stains on underlying surfaces (paving, glass, historical elements): the design of collection/runoff details and anti-drip barriers is mandatory on high-end projects.

- Detailed requirements for joints and welds: production processes, cutting and welding must comply with specific procedures so as not to compromise corrosion resistance; improper construction site interventions or the use of unsuitable filler materials can reduce durability.

The durability of Corten steel depends heavily on the exposure context and the quality of execution.

In non-critical environments (urban, with adequate dry/wet cycles), the protective patina can guarantee decades of service without drastic intervention.

In more aggressive environments (industrial or coastal areas), without protective interventions or coatings, the protection can degrade or be compromised, reducing the useful life. For this reason, the specifications must specify:

- material class;

- requirements for welding and treatments;

- details of drainage systems;

- required durability guarantees.

Applications: structures, roofing, bridges, façades, shelters

Thanks to its technical characteristics, Corten steel can be used in load-bearing structures, walkways, bridges, shelters and ventilated façades: its use is well suited to projects where aesthetics and low-maintenance durability are key values.

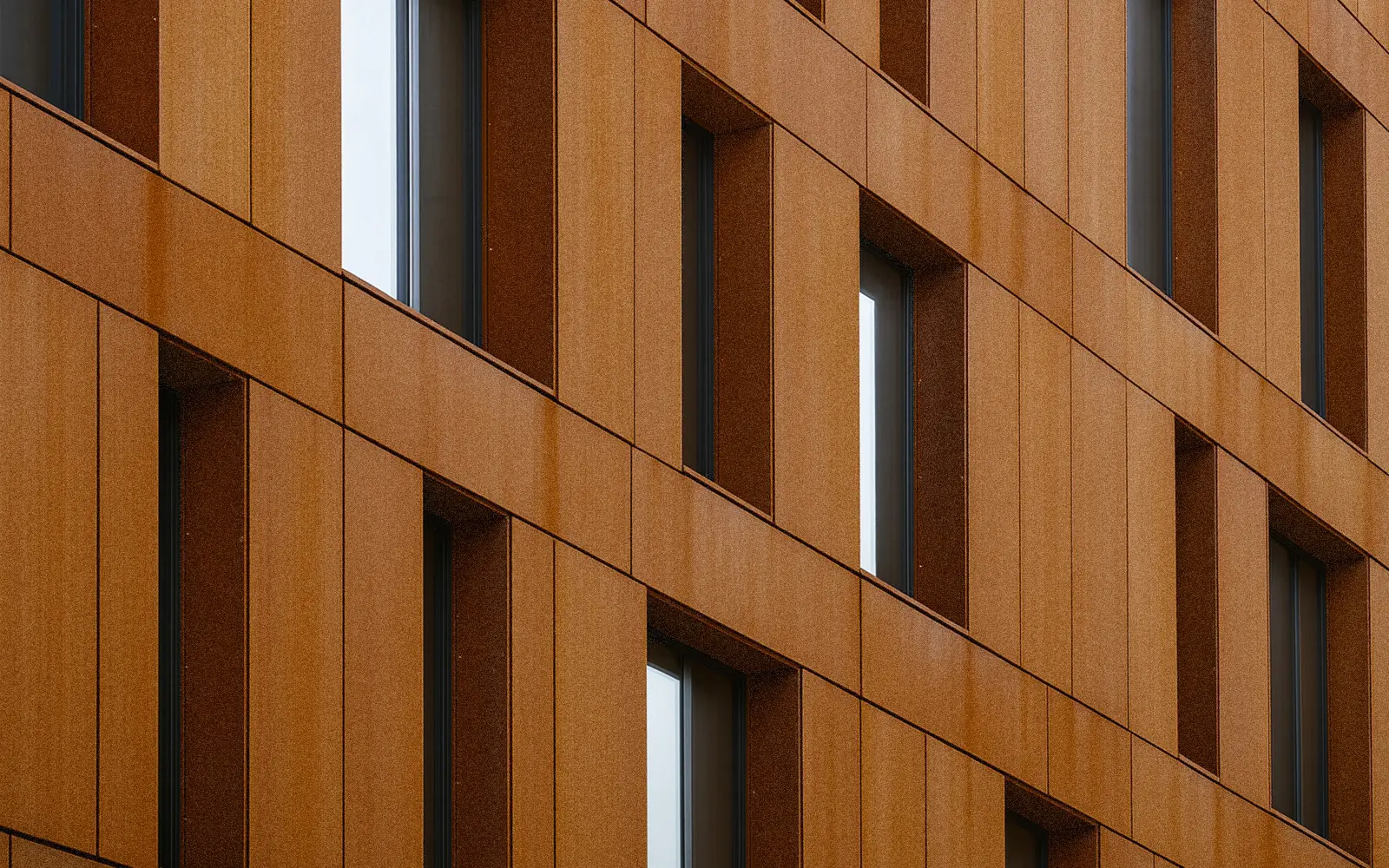

Facades and cladding

Ideal for façades that aim to create a distinctive image and require minimal maintenance, provided that drainage and runoff details are designed correctly to prevent runoff stains. One example is the new offices of Ganmar S.r.l., where Incide Engineering also provided structural and plant design services for the expansion and renovation of the headquarters.

Street furniture, shelters, roofing

Perfect for sculptures and street furniture that benefit from aesthetic evolution over time; however, it is necessary to carefully consider the impact of runoff on public surfaces in order to ensure harmonious and lasting integration.

Structures and bridges

There are numerous examples of structural uses (bridges, walkways) where the choice is dictated by the need to reduce maintenance over time, but requires careful structural design and specific regulations. Along these lines, Incide oversaw the executive design of the new Barberino bridge, which involves the construction of a Corten steel arch bridge using an integrated approach to ensure technical quality and restore a vital connection to the area that had been interrupted for ten years.

Corten steel offers a real opportunity to transform a structural or architectural project into an element of identity and resilience, but its success depends on a conscious approach: careful choice of type, definition of detailed specifications, careful design and reduced but targeted maintenance. Only in this way can aesthetics, functionality and durability converge in a high-value result.