The current deficit of the ecological supply chain is the lack of attention to material consumption, which makes it, more often than not, ineffective.

During design and construction it therefore becomes fundamental to respect sustainability in its rules, such as the lowest possible use of materials (direct eco-sustainability), given the limited resources in the world, and to choose low-polluting production processes to favour disposal in accordance with the life cycle of the materials, with the recovery of green energy.

It is from this principle that Crossed Spirals® was born, thanks to the idea of the architectural firm Enrico Rosasco: its mission is to create a sustainable solution that preserves the environment and is also extremely effective.

INCIDE Engineering engineered the architectural concept of the Rosasco studio, performing all the necessary calculations and aesthetic and shape adjustments so that this type of innovative structure would be functional and more advantageous, in terms of weight, than some traditional structures.

Discover what the Crossed Spirals ® Reticular Structure is, what it is inspired by and what its advantages are.

Presentation of the Crossed Spirals structural principle then applied to a real case.

What’s the Reticular Structure of Crossed Spiraloid Lines

Conventional buildings consist of an upper roof supported by a plurality of columns/pillars: they lack the efficient weight-relieving characteristics of the upper structure and are not sustainable.

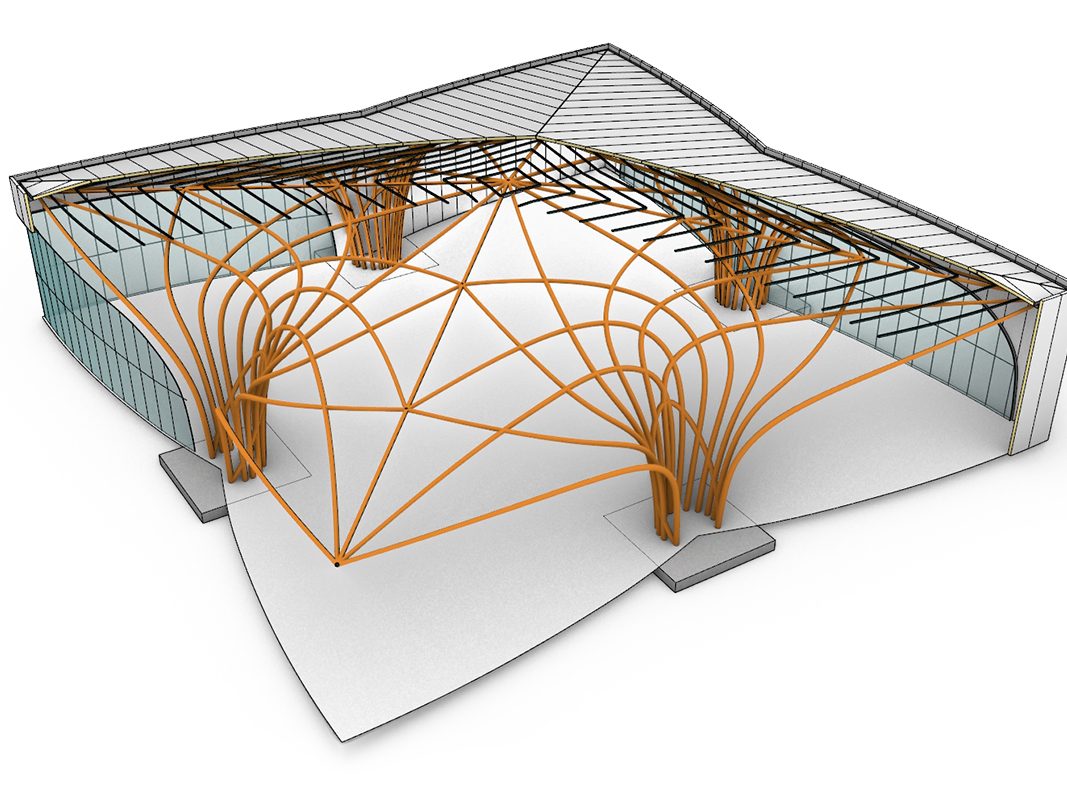

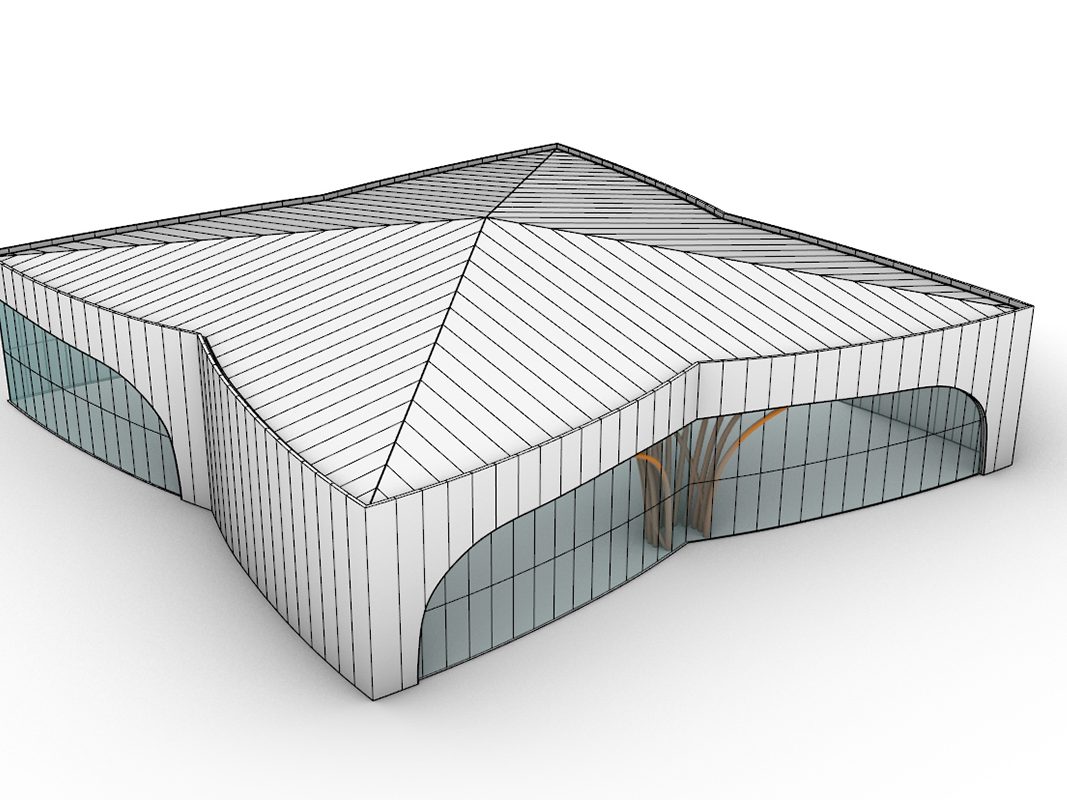

Crossed Spirals invented a building of the industrial shed or similar type, comprising an upper roof and a support system resting on the ground, configured to unload the weight of the upper roof.

The column’s constituent elements recall the behaviour of a tree trunk in which the stems (which become branches once they dissociate geometrically from the stem) form a series of small channels that transport sap from the roots to the leaves. This plurality of small channels make the tree a pre-tensioned structure whose main characteristic is its ability to absorb stresses from the canopy (crown).

Based on what has been described, it is evident that the building allows for an efficient direct discharge of stresses to the ground, as well as an even distribution of loads, achieved through direct dissipation of energy through only axial stresses and a rapid transport of stresses to the ground.

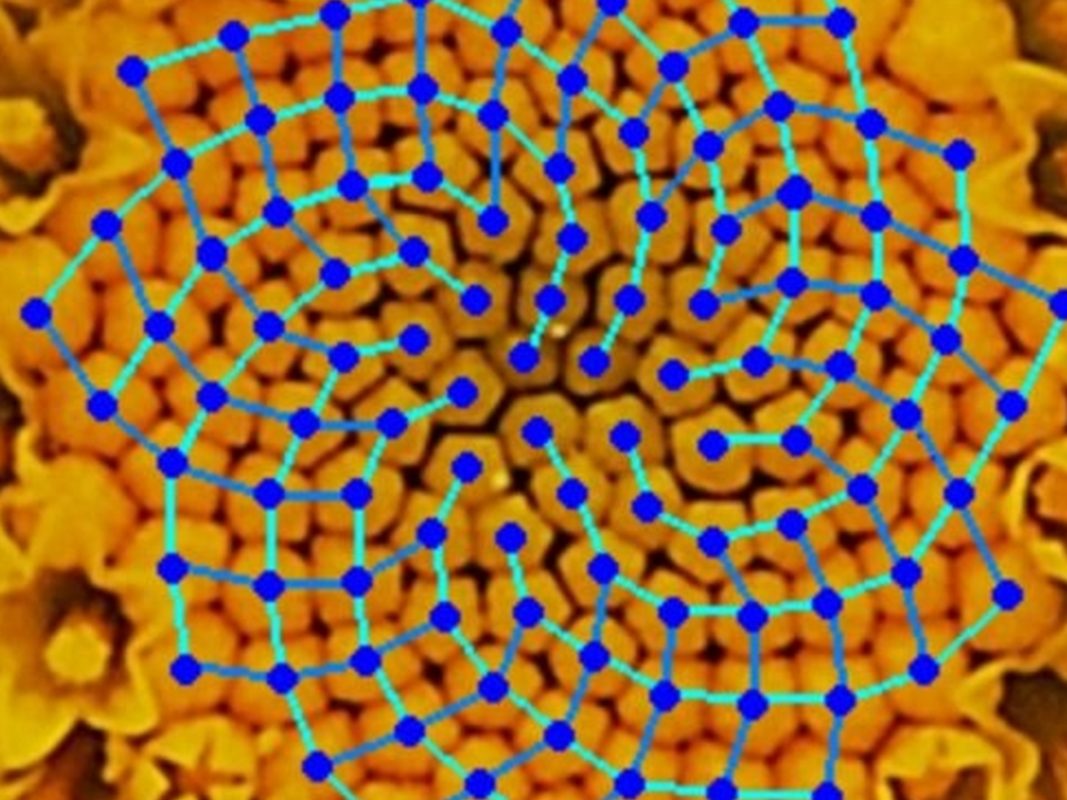

The starting point for the realisation of the Crossed Spiral Line Reticular Structure is the mathematical study of gold distributions derived from the Fibonacci sequence, followed by the study of energy dissipation solutions within natural structures, the study of convective air movements derived from the thermal gradient (Computational Fluid Dynamics), and finally the study of thermal insulation of buildings.

The structural method Crossed Spirals ® bases its approach on an equilibrium of stresses generated by actions: the crossing of spirals is the best way to achieve this equilibrium in which the stresses generated must be brought to earth in the most essential way, without generating other superfluous and harmful stresses.

Spirals, in geometric terms, have a unique characteristic that can also be found applied in nature: in the principle from which galaxies are generated, in the growth of a flower, in the development of cells and the waves of the sea, to name but a few examples.

The spiral by its definition is of a thousand shapes and is self-generating on itself by varying the angle of growth and takes on the most incredible forms, it is an evolved circle.

An engineering system needs a geometric form and the spiral is the only form that can cope with a complex system. The way to make the spirals work together is not to block them, but to cross them, to fit the complex system.

The advantages of the Crossed Spirals system for commercial buildings

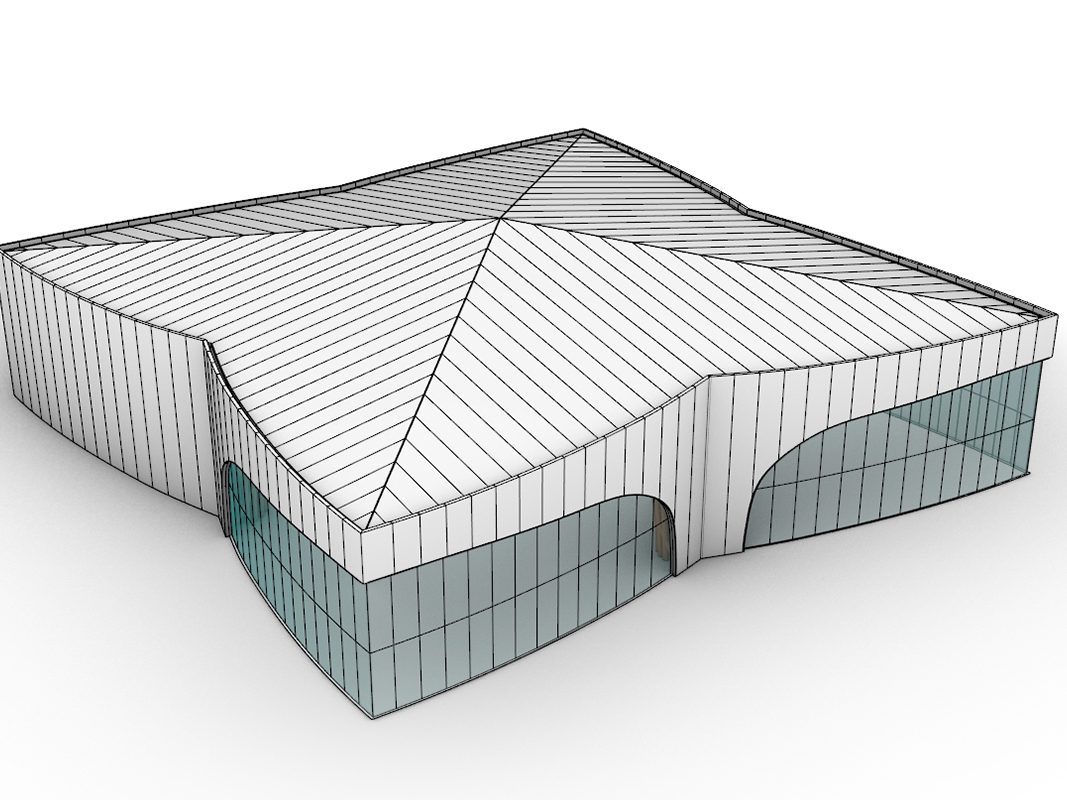

The proposed lay surface envelops the entire building and does not adhere at all points to the architectural surface but deviates from it, in a varied manner. Of course there will be a need for a secondary structure that takes the stresses from the architectural surface and returns them to the structural surface.

The proposal creates a total shell effect; there are no longer any typical, customary vertical or horizontal or sloping surfaces. The load-shedding surfaces come to represent the same flat or inclined surface that is part of the roof. Through generative design with the use of parametric softwares, an algorithm will be developed through which this extremely interesting formal typology can be managed.

This approach has many advantages:

- a lightweight supporting structure;

- the use of innovative technology to increase the strength of the rods;

- use of innovative joints that do not interrupt the elastic balance of the structural assembly;

- quick and easy assembly and disassembly;

- 100% recyclable materials;

- earthquake-proof safety;

- low and simple maintenance;

- natural ventilation using the Coriolis force method.

The integration between the structure and the building envelope followed a ‘dry’ solution, i.e. the technology known as ‘structure/cladding (or S/R) technology with a steel structure, bringing other benefits:

- ease of assembly;

- reduction of construction time, as all structural elements and envelope systems are manufactured in the workshop and ready for

- installation;

- sustainability;

- seismic safety;

- simplified site management.

Parametric approach of the Crossed Spirals principle to variable geometric figures.

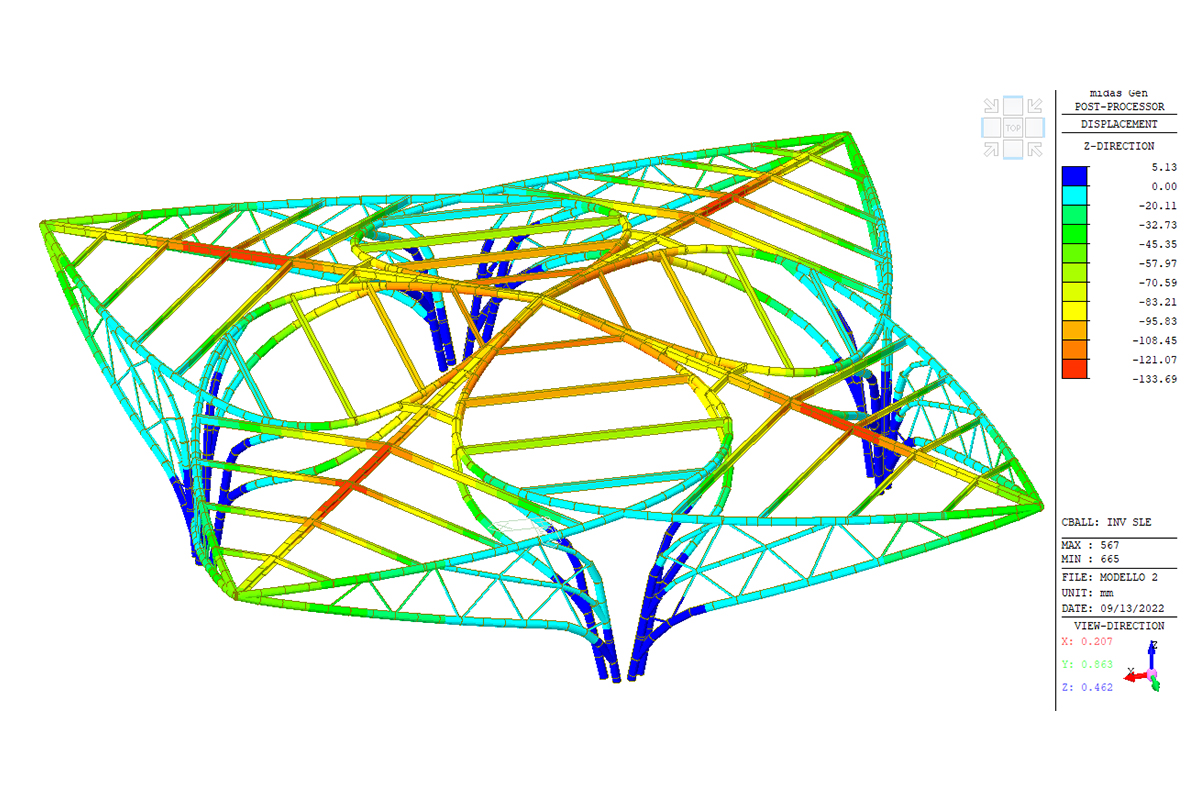

Structural FEM analysis: the results

Structural analyses using the computational finite element method (FEM) were conducted on several types of Crossed Spirals® structures. The structures analysed verified an excellent response of the Crossed Spirals® system to stress and efficient structural behaviour. The building structure is composed of steel tubular elements distributed according to the Crossed Spirals® method. The object of study is an industrial building with the following dimensions: 32x32m and a total height to the roof of 10m.

The lattice girder structure has a weight of 59 tonnes distributed as follows:

- 22 kg/sq.m. for the deck;

- 33 kg/sq.m. for the ‘organic’ pillars.