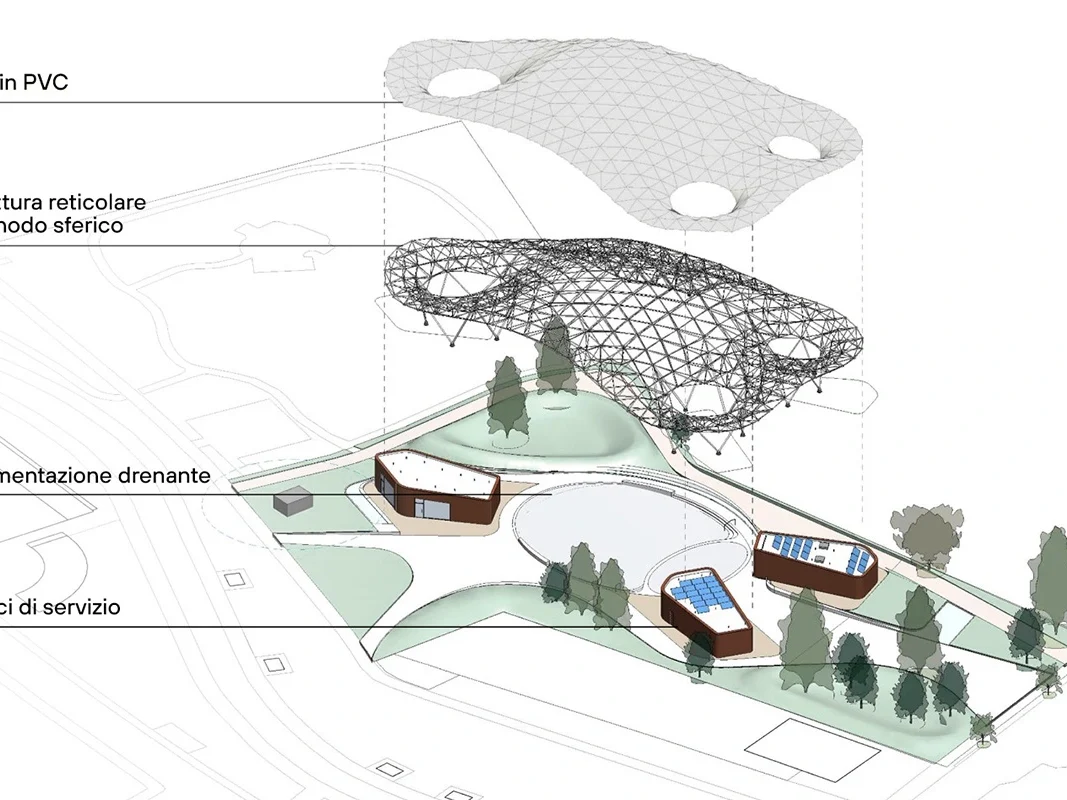

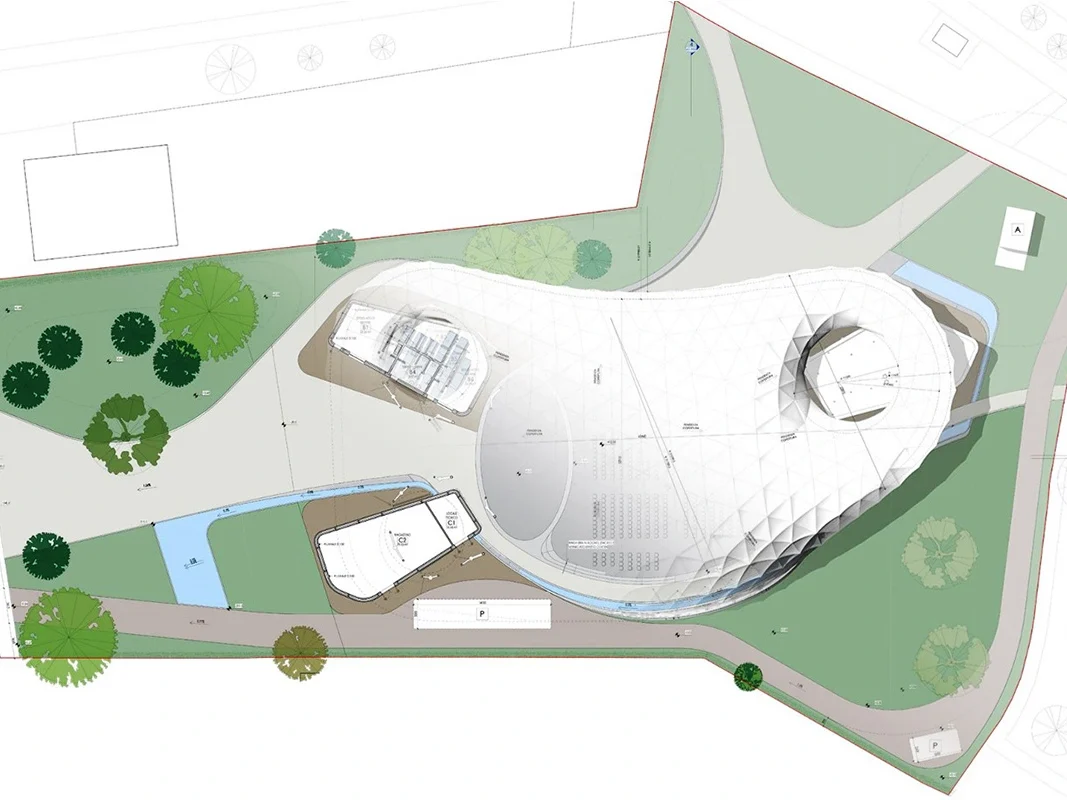

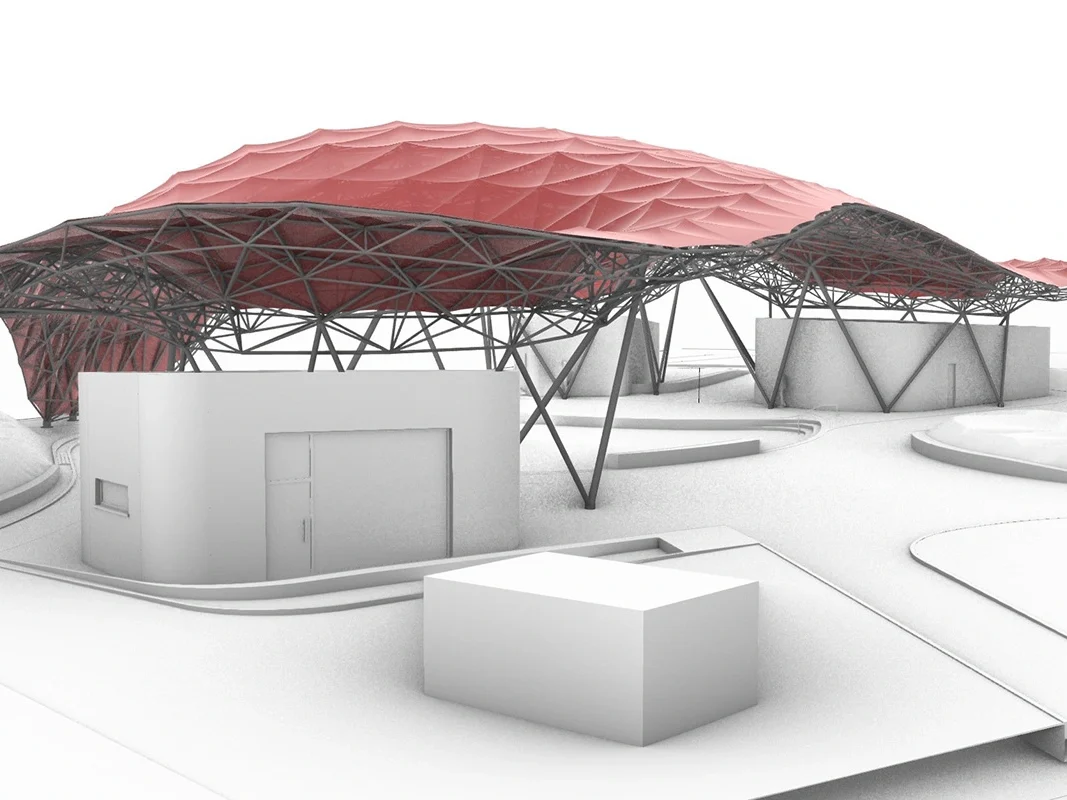

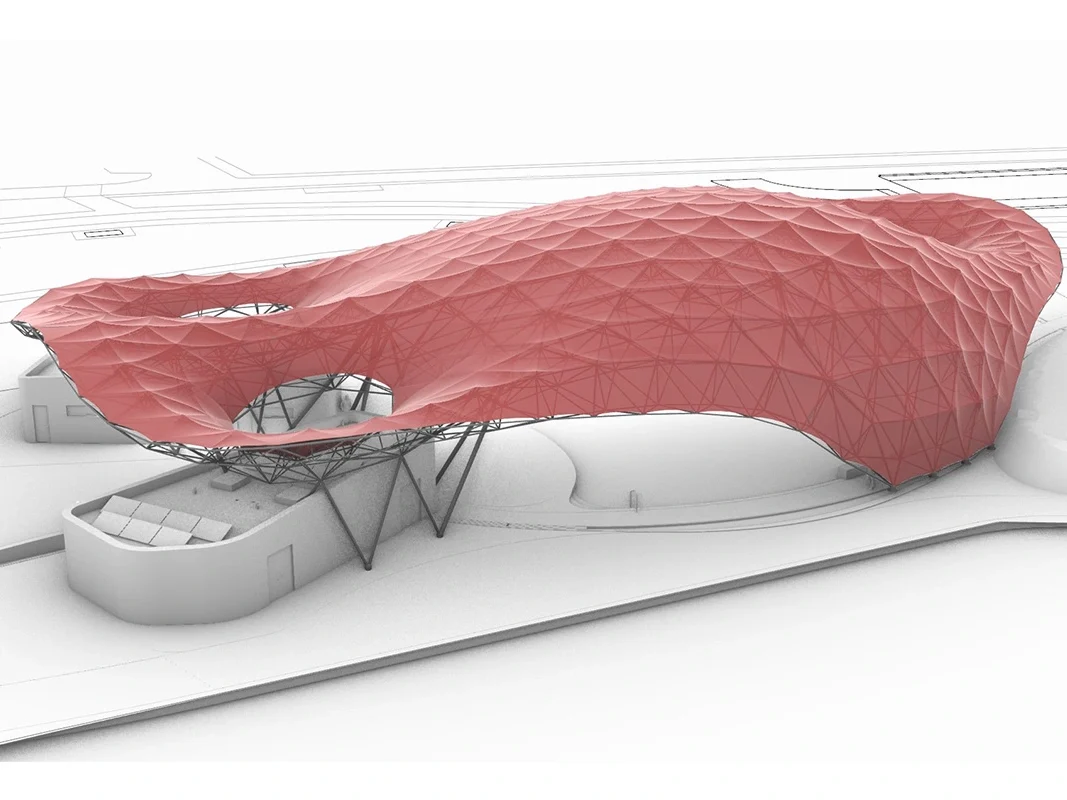

The new theatre in Abano Terme (PD) stands out as a work designed with a light and dynamic roof that interacts with the urban context while ensuring solidity and functionality.

The design challenge focused on defining a spatial lattice structure with triangular meshes, guided by an irregularly shaped three-dimensional surface with discontinuities.

This was an ambitious goal, requiring the harmonisation of aesthetics, construction constraints and structural efficiency.

To address this, a parametric design approach was adopted, capable of transforming geometric complexity into a feasible system, optimised and developed through an integrated process involving design, engineering and production. The architectural concept was defined in collaboration with the Municipality of Abano Terme (PD), while the definition of the guide shape and the lattice structure was developed internally and refined to ensure full integration with the systems supplied by Canobbio for the fabric and by MERO for the metal structure.

Let’s take a closer look at the application of parametric design and its advantages in this innovative project.

The logic of parametric design

The starting point was the choice of a spatial lattice structure composed of two overlapping surfaces with triangular meshes connected by diagonal elements.

This solution proved to be the most suitable for ensuring strength, feasibility and cost control, given the formal complexity of the roof.

The modelling process was developed in several stages:

- definition of the guide surface;

- definition of the upper mesh and the sheet;

- definition of the lower mesh and the connecting diagonals.

Let’s take a closer look at the approach adopted.

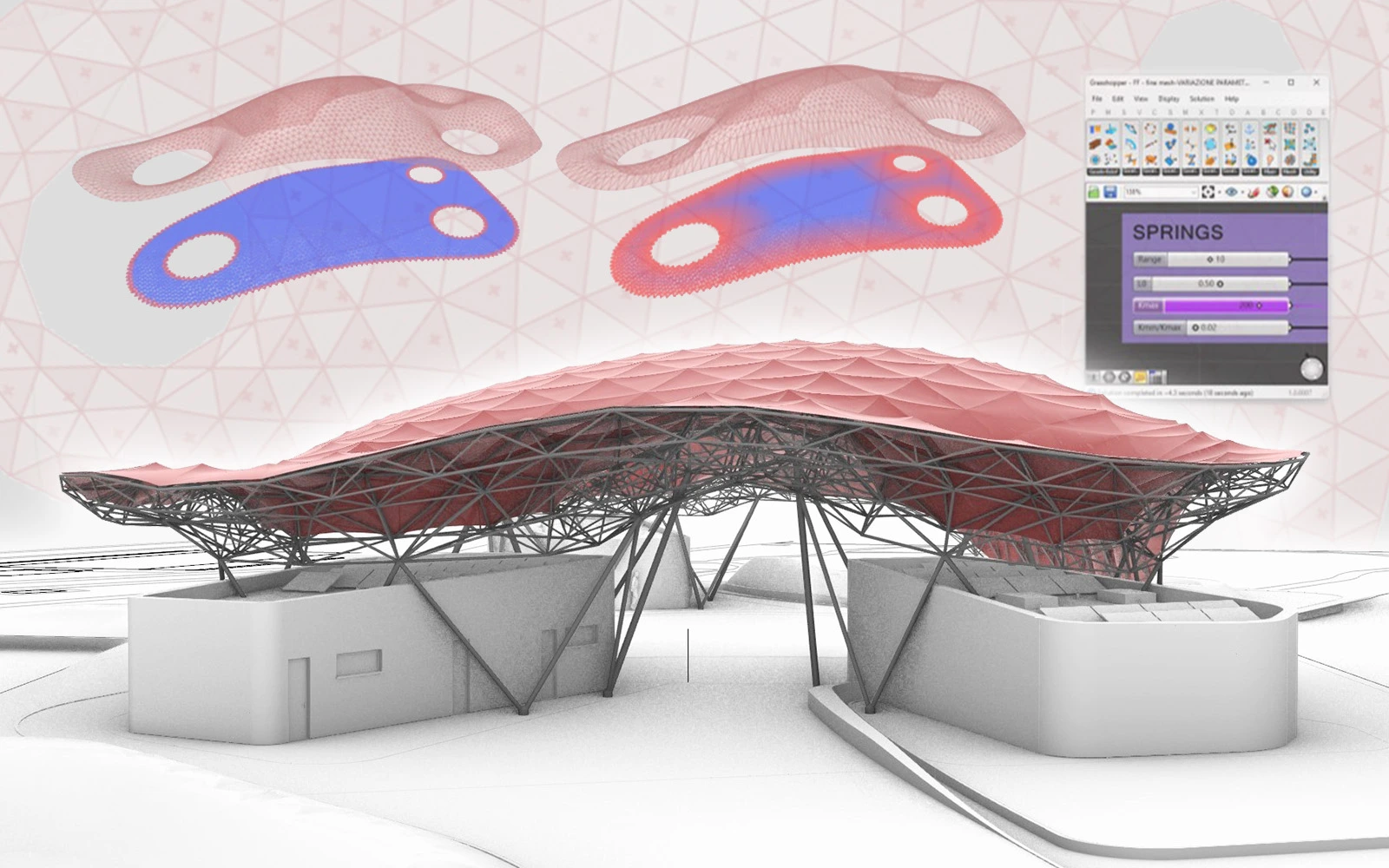

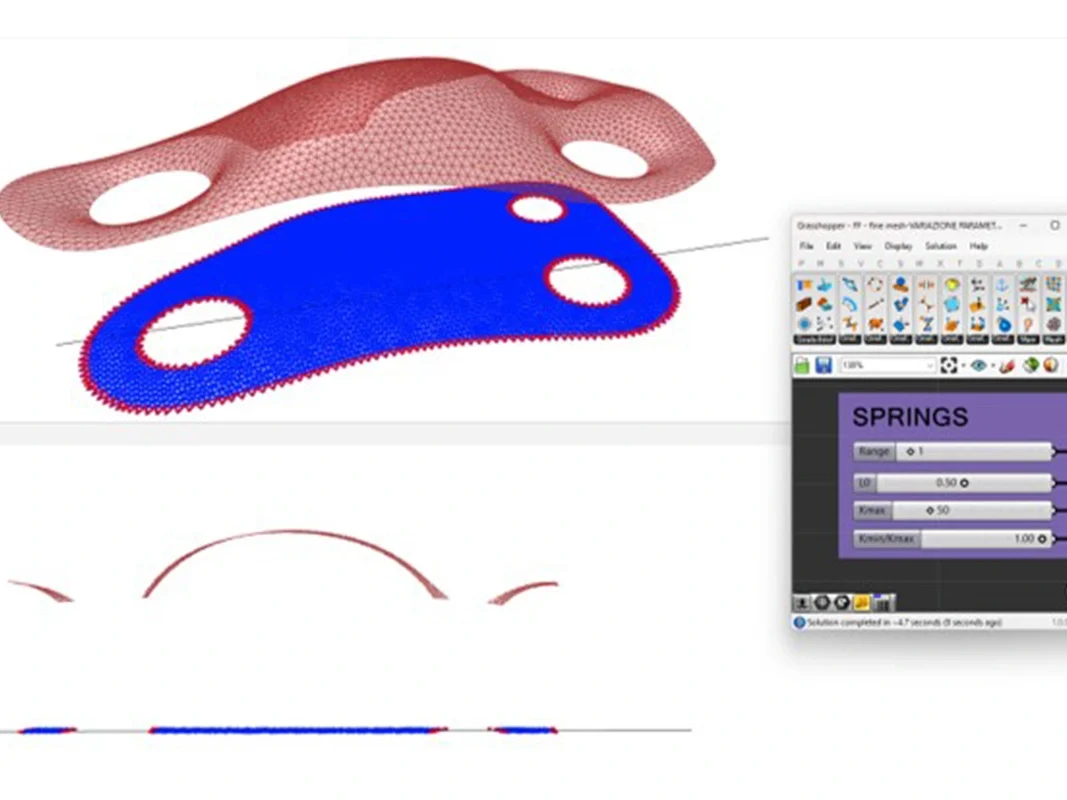

Form finding with Grasshopper and Kangaroo

The team adopted a parametric form-finding approach based on the use of Grasshopper and its Kangaroo plugin.

The principle is simple: by applying forces (pressure, traction, gravity) and constraints (edges, elasticity, flatness) to an initial mesh, the model evolves until it finds a balanced form.

In the case of this theatre, three parameters guided the generation of the surface:

- position of the constrained edges, external and internal to the cones;

- stiffness of the mesh, which can be modulated in the various areas of the surface to accentuate the verticality at the cones;

- force field, to modulate the extent and direction of the surface deformation.

Thanks to this method, each input change automatically updated the overall surface, eliminating discontinuities and returning a continuous and harmonious covering.

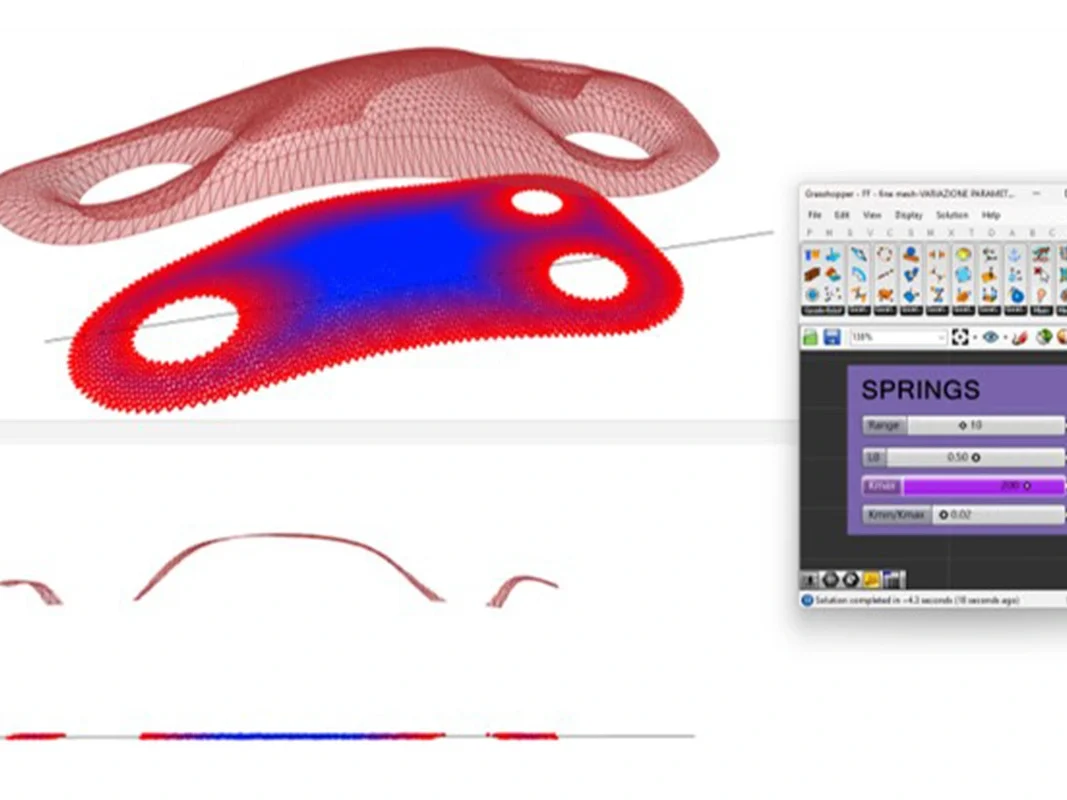

Geometric challenges: from flat surfaces to complex shapes

In an ideal case, the 3D mesh can be generated from a rectangular surface: regular triangulation, second layer obtained with a simple offset and connecting diagonals.

However, the roof of the Abano theatre is not a regular surface. Its shape, which can be traced back to three deformed cones joined together, would have generated meshes that were too irregular and unworkable nodes, with rods of uneven lengths and angles.

To overcome these critical issues, it was necessary to develop a parametric approach capable of producing a continuous geometry that was optimised and consistent with the construction and material constraints.

The generation of the structural mesh

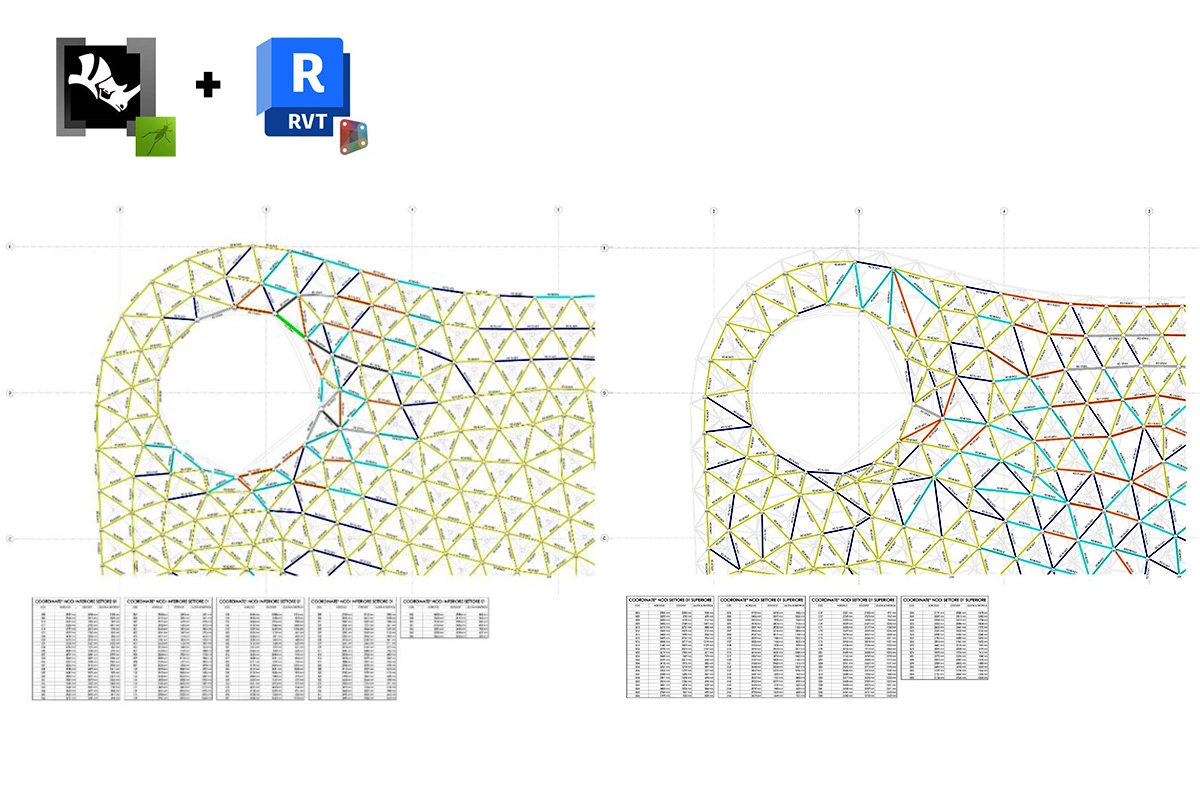

Once the guide surface had been defined, the first layer, intended to accommodate the fabric, was triangulated. The length of the rods was checked using a circle packing algorithm to ensure uniformity in the length of the rods and regularity of the nodes.

The second layer was generated using a progressive, non-constant offset that varies according to the distance from the edges and cones. Here too, the parametric approach allowed irregularities to be corrected manually, maintaining a balance between automation and design control.

The complete structure—first layer, second layer, and diagonals—was then verified using FEM calculations.

Once the modelling was complete, the structure was exported to Revit via a direct link with Rhino, so that the parametric model could be integrated into the BIM process. This step made it possible to coordinate all disciplines and produce the final documentation.

The main advantages of parametric design

The adoption of parametric design, supported by the use of Grasshopper and form finding with Kangaroo, made it possible to tackle a complex process such as that of the Abano Theatre in a much more fluid and effective manner. The modelling of the reference surface, the basis for the subsequent grid, was managed dynamically: each variation in the three main inputs generated an immediate and consistent update of the entire model, without the need to manually correct individual points.

This approach offered several concrete advantages: fast and repeatable modelling, which significantly reduced development times; optimised global logic, capable of replacing most manual interventions with a consistent and automated system; and, finally, aesthetic and structural optimisation, as the model was recreated each time in its ideal arch/dome shape, ensuring a balance between architectural expressiveness and construction feasibility.

The Abano Theatre project demonstrates how parametric design is a method for tackling complex geometries, reconciling aesthetics, efficiency and constructability, as already demonstrated in other projects carried out by Incide, such as the Grand Theatre in Rabat and the parameterisation of industrial buildings.

Thanks to form finding, optimised triangulation and collaboration between the various players, the reticular structure has become a concrete example of how technology can support architectural creativity and turn it into reality.