For many years, the architecture, engineering, and construction industries have relied on BIM, to design and engineer buildings and infrastructure projects. Because of its benefits, BIM adoption is growing rapidly for plant projects as well.

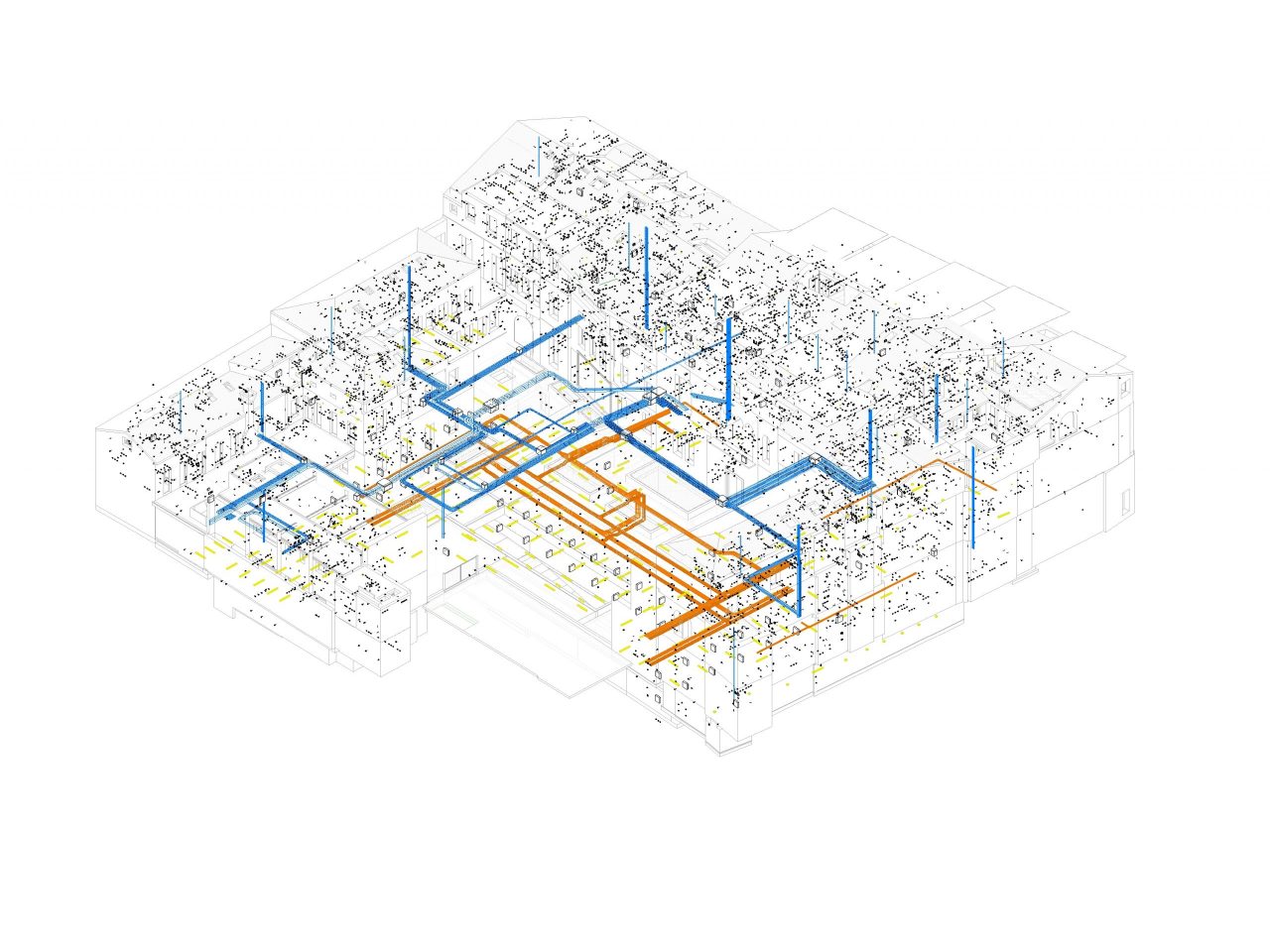

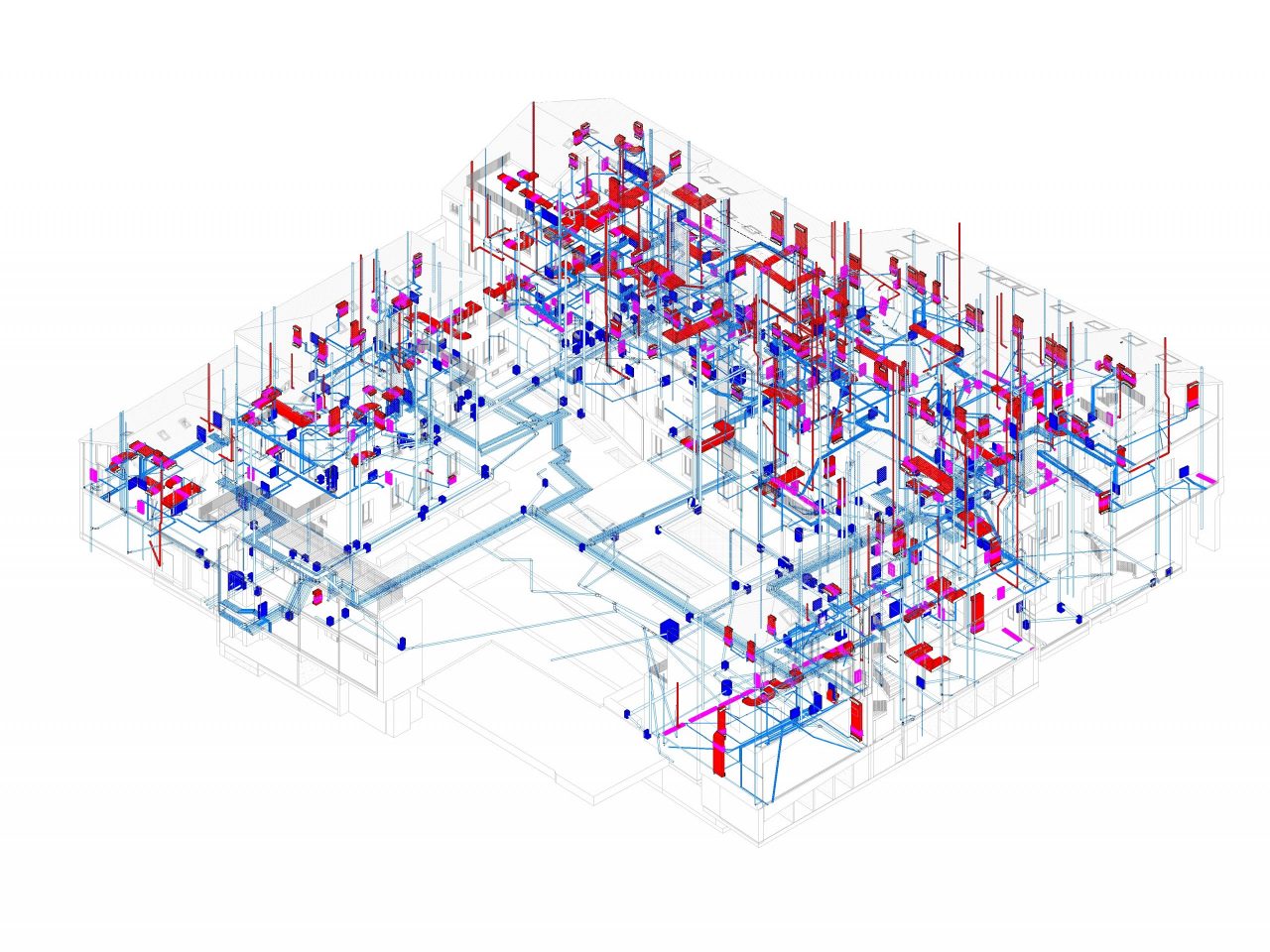

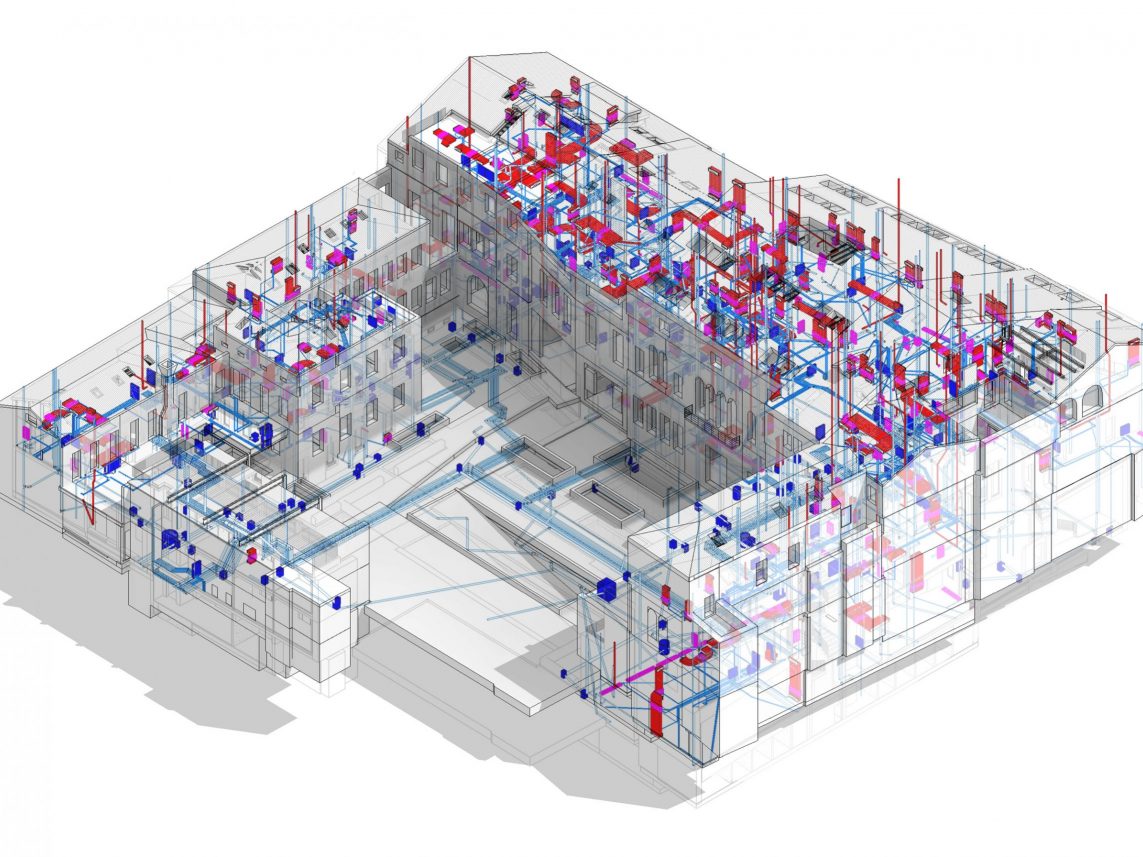

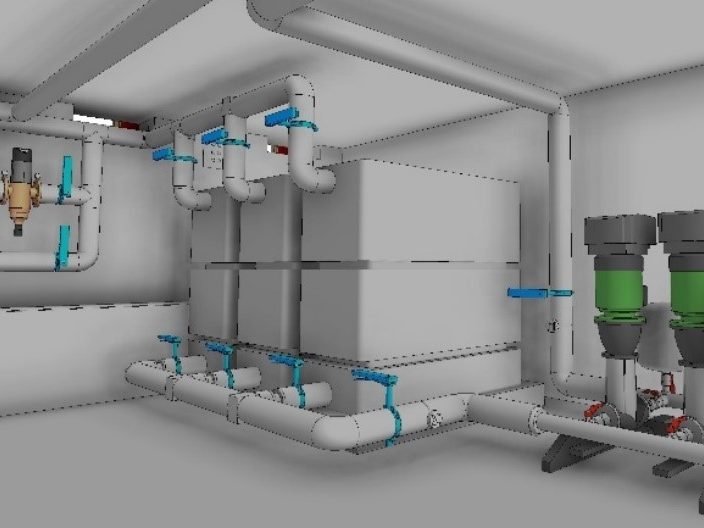

Mechanical design in a BIM environment is defined with the achronic MEP (Mechanical, Electrical and Plumbing). The possibility of having an MEP model together with an architectural model, therefore already during the design phase, is the starting point for a better system solution. With MEP design you have the advantage of designing electrical or hydromechanical systems always operating on the same model and obtaining a lot of information without asking other users.

By itself, in fact, BIM is not a tool or a software solution. It’s best to think of BIM as a better way of managing project information in a shared repository where the same set of plans and designs can be prepared, viewed, updated, modeled, and finalized by any and all project stakeholders simultaneously.

The challenges of plant design as a driver for the adoption of BIM

Many countries around the world are introducing mandates for the use of BIM in civil engineering projects. This is driving process plant designers in the water and wastewater industries in particular to adopt it today.

According to the Dodge Data and Analytics SmartMarket Report, The Business Value of BIM for Water projects, 88 percent of companies that design and build water and wastewater facilities are already using BIM.

Urbanization and the ever-expanding city

Today, 55 percent of the world’s population live in urban areas. That is expected to increase to 68 percent by 2050, according to the United Nations. Urbanization combined with the overall growth of the world’s population could add more than 2.5 billion people to urban areas by 2050. Growing populations are pushing aging water, wastewater and other plant infrastructure to the breaking point, so designers and engineers are turning to BIM to help build more capable facilities faster, more efficiently, and sustainably.

Top 5 benefits of BIM for plant design

There are many good reasons to switch to BIM and many of them are related:

1. Minimize errors and omissions

Quite simply, errors occur when designers, architects, and engineers from the different disciplines and backgrounds fail to communicate effectively. When construction teams go to install pipes and there is a wall in the way, that’s a problem. BIM tools not only help keep designs coordinated and up-to-date with capabilities like data validation — checking to ensure designs are consistent and adhering to project-specific requirements — they also actively assist in clash detection and remediation. Likewise, many omissions, where something is simply left out of the plant designs only to be discovered during construction, can be avoided b using up-to-date models that can be checked and cross-checked byeveryone involved. In this way, as plans are updated by other disciplines like architects or civil engineers, plant designers are alerted to those changes and can make adjustments as needed.

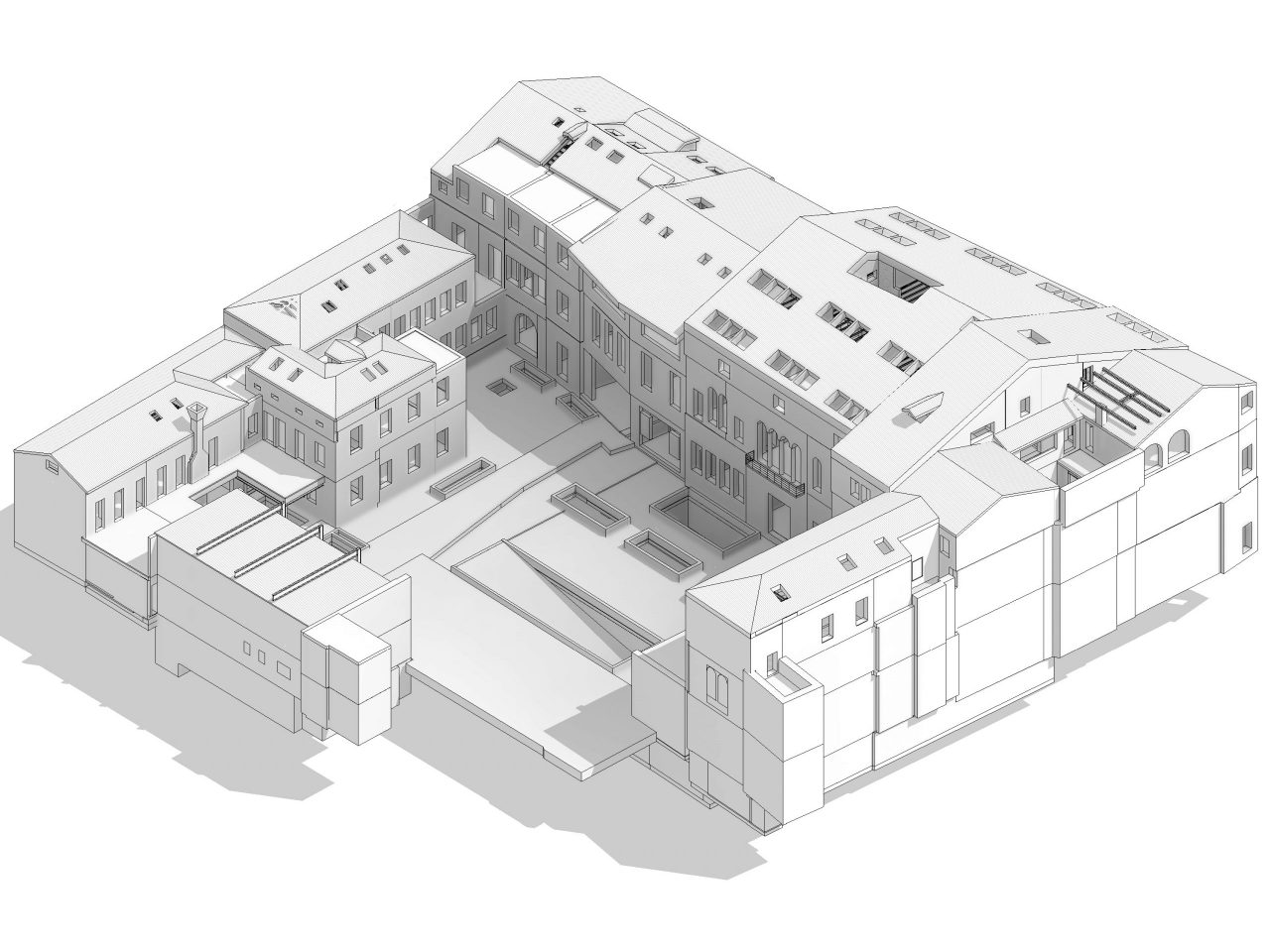

2. Better design through visualization

One of the other big benefits of using BIM is being able to combine information, plans, and designs to create visuals that can accurately represent what the final plant will look like and to easily share them. Ultimately, this leads to better, more innovative designs. This makes sense since these benefits cascade down through the rest of the project lifecycle. Use of BIM tools can yield a more well-reasoned design, informed by analysis and simulation, that can more effectively achieve project goals. This can encourage more innovation on projects as well as save time and costs.

3. Optimized collaboration

It is consistently listed as the first reason designers, architects, and builders adopt BIM. This is because BIM acts as a focal point and clearinghouse for all plans, designs, build sheets, specification data, costs,

and schedules. But BIM takes collaboration a step further by allowing multidisciplinary teams of plant designers, architects, and building engineers to co-create in near real-time. This minimizes the constant back and forth that typically goes on using email. It saves time and effort, while reducing the number of friction points in the process.

4. Improved cost management

By improving the ability of all stakeholders to see and work with 3D models even before construction begins, BIM enables better cost control and even cost reductions and also plays an important role in improving constructability.

5. Faster project startup

While many of BIM’s benefits stack up quickly once the project is underway, a more integrated design solution also enables a project to kick off faster. For example, in urban areas where space is limited and existing plants must be refurbished, a lot of the information about these facilities is either missing, wrong, or out of date. Using reality capture technologies, designers and engineers can image the plant inside and out and then feed the BIM model with accurate 3D images to create a digital twin. The model can then be populated with up-to-date information about elevations, pipe runs, instrumentation, etc. that also includes meta-data about each.

Through integrated design, BIM connects structural engineers and architects working outside the plant to what plant designers are doing inside.

As highlighted, BIM is an excellent way to navigate the highly complex and multidisciplinary environment of plants in a way that saves time and money, leading to better results for all stakeholders involved. This is why Incide Engineering adopts the BIM methodology in the projects, to guarantee the optimization of times, costs and communications.

If you were interested in this article, see also:

- Electrical and mechanical systems engineering

- Industrial plants: the services of Incide

- 10 reasons to work in BIM