Bridge design is a multidisciplinary process that combines structural engineering, geotechnics, architecture, construction management and economic planning, often seeking solutions that balance safety, durability, cost control and urban value.

We take a comprehensive look at the key stages of design, fundamental loads and checks, the integration of architecture and engineering, risk mitigation strategies, BIM-based digital flows and real case studies by Incide Engineering that demonstrate concrete applications.

Architecture and engineering: how they are integrated into bridge design

The balance between aesthetic value and engineering logic is crucial for projects destined to become urban landmarks. Architecture defines the user experience, perception and inclusion in the urban fabric; engineering guarantees performance, safety and durability. In marine/mountainous or aggressive environments, for example, materials with anti-corrosion protection or specific materials (such as Corten steel) are selected, construction details are defined to prevent water stagnation, and periodic maintenance interventions are planned. Accessibility for inspection is a non-negotiable design requirement.

Choice of structural type (stayed, arch, truss, suspended)

The choice of type is guided by: light to be covered, environmental impact, costs, construction times and aesthetic requirements. Some guidelines:

Beam/Truss

Efficient for small to medium-sized lights and prefabricated solutions.

Arched

Suitable for medium and large lights, with high compression efficiency.

Cable-stayed

Ideal for long lights with slender elements and strong visual impact.

Suspended

Option for large spans, requires careful design of towers and anchors.

How aesthetics and engineering logic find a balance

Integrated design involves workshops with architects and engineers from the earliest stages to support cost-effective design choices. The use of parameterised models allows aesthetic scenarios to be evaluated with measurable structural and constructional impacts.

Evaluating alternatives through multi-criteria analysis (cost, durability, environmental impact, ease of maintenance) allows solutions to be selected that maximise value for the client in the medium to long term.

The key stages of bridge design

Bridge design is divided into progressive stages: in each stage, experimental data is collected, numerical models are developed, and architectural and operational requirements are integrated. Design principles and structural checks are based on Eurocodes, which provide load actions and combinations, details for fatigue, and guidelines for modal analysis.

Analysis of the territorial context and geotechnical conditions

The site analysis includes topographical surveys, geotechnical investigations (penetrometric tests/core sampling), sampling, on-site and laboratory tests, study of hydraulic conditions and assessment of environmental and landscape constraints. Soil-structure interaction profoundly influences the dimensioning of foundations, the choice of plinths, piles or micropiles, and the overall response to seismic and thermal actions. Thermal expansion and structural joints must be evaluated taking into account the span, the materials chosen, and local climate variability.

In particular, we would like to mention:

- Initial surveys: geotechnical investigations and topography, often carried out using drones for very large areas or laser scanners for detailed areas.

- Hydraulic assessment: flood flows, currents, erosion phenomena.

- Environmental constraints and easements: protected areas, existing infrastructure, pipelines and services.

Feasibility study and preliminary assessments

The feasibility study evaluates typological solutions (beam, arch, cable-stayed, suspended), preliminary cost estimates, environmental impact, feasibility, launching methods and construction times. The preliminary design assumptions are defined – typical section, spans, number of spans, estimated dead weight – and an initial assessment of the loads is carried out in accordance with the applicable regulatory principles. Logistical constraints are assessed: space for assembly, accessibility for lifting machinery, impact on existing traffic.

The output of the study is the structural concept, the preliminary cost estimate, and the operational limits for the construction site.

Structural modelling and choice of materials

The choice of materials affects durability, maintenance and fatigue behaviour. Bridge steels, high-performance concretes, composite materials and mixed solutions are selected according to spans, traffic loads and corrosive environments. Fatigue assessment is crucial for bridges subject to heavy rail or vehicle traffic: repeated stresses are evaluated to estimate the residual life based on construction details.

Common materials are structural steel for girders and light structures, reinforced or prestressed concrete for decks and piers, and glass and steel for architectural elements such as pedestrian walkways.

For durability, the strategies to be evaluated are surface protection, connection insulation, effective drainage, and accessibility for inspection.

Advanced calculations, verifications and simulations (BIM, FEM, digital twin)

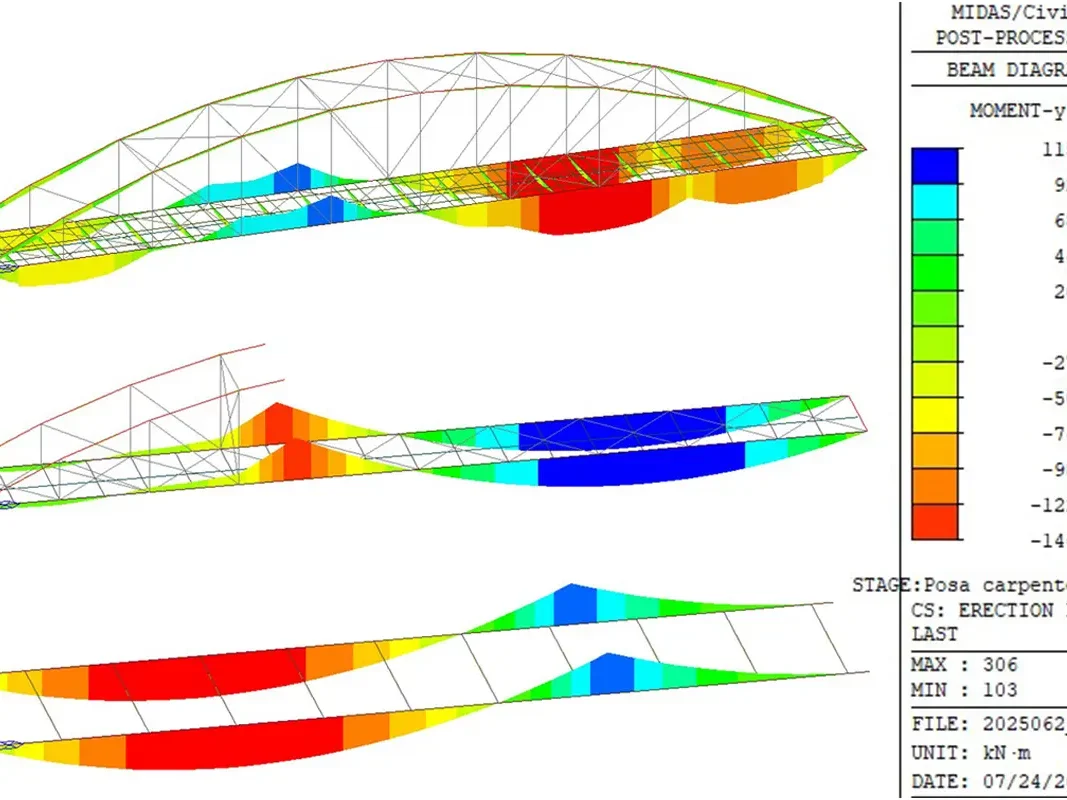

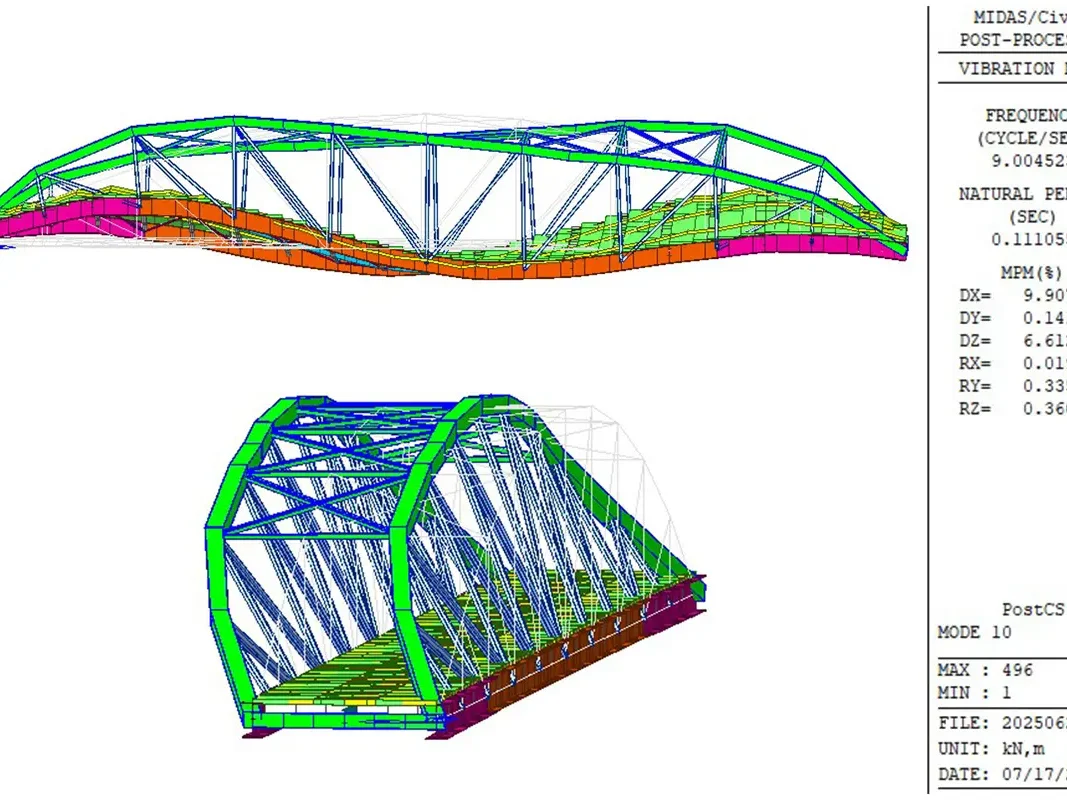

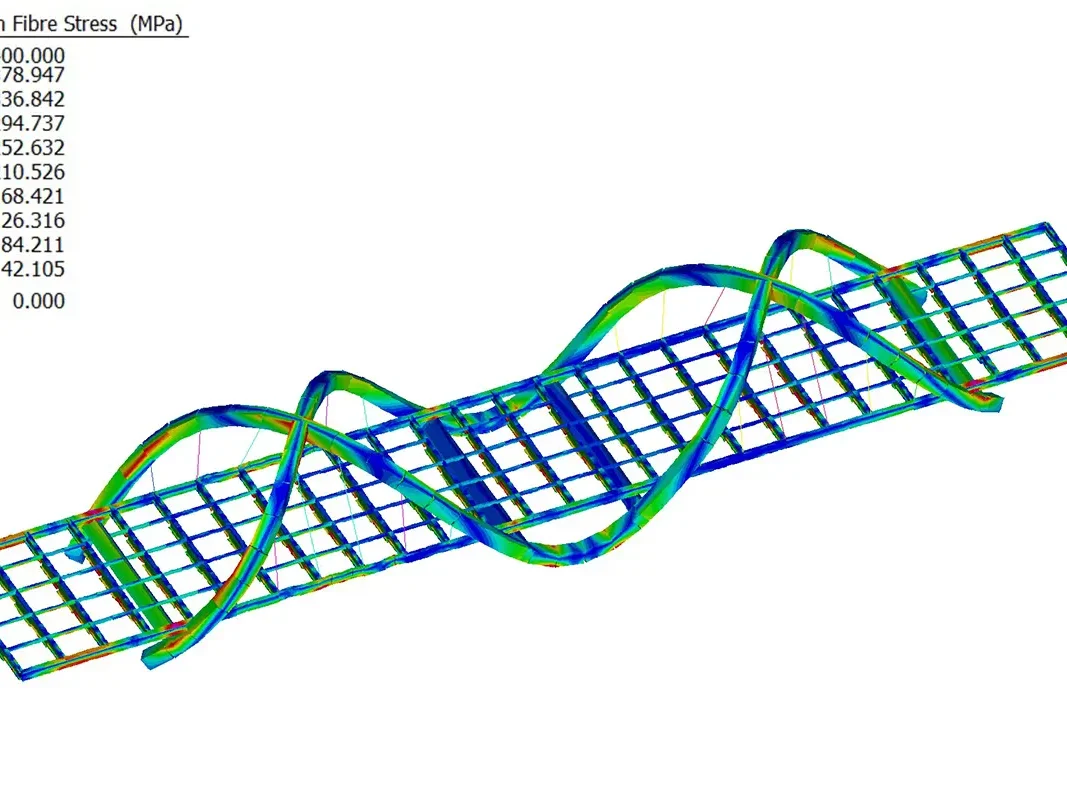

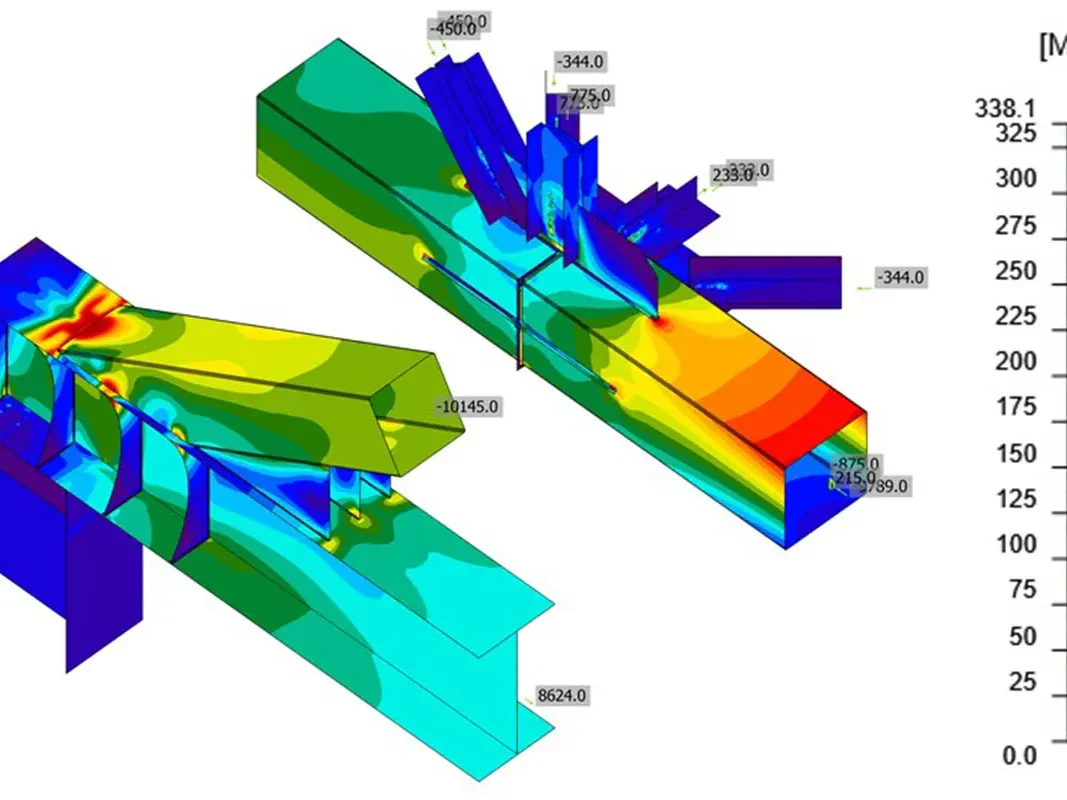

Modern design is based on advanced FEM analysis, dynamic modelling and integrated digital flows. Modal analyses, non-linear checks, vibration response simulations and fatigue studies are performed. The use of BIM facilitates multidisciplinary coordination and integration of FEM model data, while the concept of digital twins enables operational monitoring and predictive maintenance.

- Types of FEM analysis: 3D mesh, modal analysis to evaluate characteristic frequencies, non-linear analysis for large displacements or instability phenomena. In the presence of significant spans, concentrated masses or activities that can generate vibrations (e.g. rail traffic), modal analysis is essential.

- Simulations required: response to traffic loads, wind, earthquake and verification of global and local stability.

FEM modelling allows the structure to be represented with different levels of detail:

- 3D mesh: for complex joints and local checks.

- Modal analysis: determines natural frequencies and modal shapes useful for assessing resonance risk.

- Non-linear analysis: for large deformations, local plasticisation, instability.

Stability checks (buckling), vibrational response and distributed stiffness analysis are performed using FEM models integrated with material data and boundary conditions.

Types of loads: what to consider

Loads on bridges include permanent actions, variable actions (traffic), dynamic loads and exceptional actions (impacts, accidents). Understanding the differences and analysis methodologies is essential for structural safety. In particular, the following are distinguished:

- Permanent loads (G): dead weight of structures, fixed superstructures, installations and cladding.

- Accidental loads (Q): vehicular and rail traffic, pedestrians, snow, variable distributions over time.

- Dynamic loads: amplifications and forcing due to moving vehicles, impacts, turbulent wind and resonance phenomena.

The design requires load combinations that include dynamic amplification factors to take into account the effects of impact and vibration.

In addition to loads, it is important to consider other factors such as:

- Traffic: specific load maps apply to road and railway bridges, including exceptional transits and train mixes.

- Wind: aerodynamic analysis for light and long-span bridges (flutter, vortex shedding). For particularly long spans, computational fluid dynamics can guide the aerodynamic design (CFD analysis).

- Earthquake: seismic actions checked according to code; the overall response depends on soil-structure interaction and the dissipative characteristics of the joints and the type of restraint/support system provided. In the event of significant seismic stresses, isolation/dissipation mechanisms (such as shock transmitters) may be provided as necessary.

Dynamic loads: differences and analysis

Dynamic loads are temporary forces that are not always repetitive (e.g. impact, transient wind) and can lead to instability or resonance phenomena in which the structure can experience large displacements even under moderate loads. Modal and time-history analysis is the tool used to assess these issues and adequately dimension damping and stiffness.

Cost/time optimisation and risk management

Optimisation integrates LCCA (Life Cycle Cost Analysis) assessments, site logistics, prefabricated solutions to reduce assembly times and risk mitigation strategies (milestone contracts, contingency plans). Parametric modelling and simulation of construction processes allow for testing assembly sequence scenarios and reducing interference with traffic and the environment.

In this scenario, prefabrication techniques, high-altitude assembly with modular construction sites, and a Lean Construction approach to minimise waste are useful.

Digital design and BIM workflows

The adoption of BIM for infrastructure (BrIM) is now an established practice for improving coordination, cost control and design quality. The information model becomes a control tool in the life cycle of the project because it centralises geometric data, material properties, calculation data and maintenance plans. It allows automatic extraction of quantities, activity scheduling and integration with sensors for operational monitoring.

Clash detection reduces conflicts between structures, systems, architectural components and services, limiting errors on site. An efficient multidisciplinary coordination process reduces rework, risks of delays and contractual disputes.

The integration between BrIM and management systems (CMMS) allows for the planning of interventions, tracking of work and optimisation of expenses throughout the entire life cycle, transforming the digital model into a management asset.

Safety and risk mitigation

Safety includes both the design and execution phases, as well as operation. The resilience of structural elements and the ability to manage extreme events are priorities.

Integrating inspection routes, access points and monitoring systems from the execution phase onwards simplifies maintenance activities and reduces costs. Tools such as monitoring systems and digital twins enable predictive analysis of structural health. Other key elements include inspection access points, anchor points for access devices, and materials with a documented maintenance history.

To increase durability and resilience, protection against corrosion and atmospheric agents and the implementation of emergency plans for hydraulic events, fires, and ship or vehicle collisions are essential.

Real cases: applications and results in Italian and international projects

Below are two emblematic cases that showcase Incide Engineering’s integrated design approaches.

Al Raha Bridge (Abu Dhabi): bridge with a total span of 83.6 m divided into three spans and a total width of 29.4 m to accommodate four lanes, quays, pavements and a pipe compartment. The project required attention to nodal connections, assembly sequence and load management for local climatic conditions.

Barberino Bridge, Bobbio (Piacenza): Structural design of a 74-metre single-span arch bridge in Corten steel to replace the old masonry arch bridge, which had collapsed on several occasions. The project involved the complete executive design, with particular attention to the assembly of the bridge itself, which was very complicated given its particular location and the rather limited assembly space.

Val d’Arve Bridge (Geneva): this project was characterised by the integration of the main structure and glass cladding; particular attention was paid to the connections in relation to vibrations caused by passing trains and environmental requirements, with a detailed handling and assembly sequence.

Humanity Bridge, Chelyabinsk (Russia): Structural design of a cable-stayed bridge with steel box girder deck, two 61 m spans and concrete foundations. The project includes structural modelling, dynamic stress analysis, design of prefabricated blocks in the workshop and optimisation of the assembly phases to ensure a continuous urban connection between the two parts of the city.

Bridge design requires an integrated approach that combines geotechnical analysis, advanced structural models, fatigue assessments, construction strategies and digital processes such as BIM and digital twins. Investing in accurate FEM modelling, multidisciplinary coordination and maintenance planning leads to safer, higher-performing and more sustainable results over time. Real-world cases show that design experience, attention to detail and the adoption of digital workflows transform complex engineering challenges into reliable, high-quality structures.